AR09058350 “Developing and introducing the production technology of chrome antifriction cast iron for parts of the mining equipment”. Project manager Shcherbakova E.P.

Relevance

A number of parts of the mining equipment are made from chrome cast iron. In spite of significant advantages of using this cast iron, it also has its disadvantages – relatively poor casting properties (low fluidity, high shrinkage), besides, machining is complicated when making the parts from cast products.

The project purpose

Development and introduction of the parts’ production technology of mining equipment, made from chrome cast iron with an optimal set of properties, depending on operation conditions of the parts, which will increase a life cycle by 1.5-2 times.

Expected and achieved results

The analysis of existing technologies and modern production methods of the spare parts of dredge pumps has been made. The spare parts of the dredge pumps have been identified as an object of research, because a significant part of them is made from the chrome cast iron and high antifriction properties are required from them. It has been shown, that at the moment, the main trend of improving the efficiency of mining equipment operation is increase of wear resistance and hardness of the materials, used to manufacture large spare parts. Moreover, quantity of the works, devoted to studying the materials, used for manufacturing small parts is not enough. Meanwhile, the small parts are a “bottleneck”, as they fail more often. The made analysis and local monitoring has shown, that the small parts of the dredge pumps (bushings, shafts, etc.) fail more often than the large parts (wheel, armored discs), that reduces the efficiency of pump operation. The small parts, as a rule, are made from antifriction materials (cast iron), because they work at the junction points.

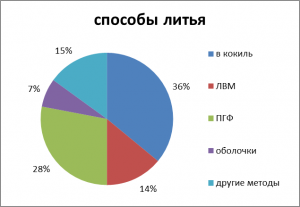

The analysis of casting technologies for manufacture of the small cast products on the territory of the Republic of Kazakhstan has been made. A recommended production method, taking into account the fixed assets of the Republic of Kazakhstan, is to cast in the green sand molds, with the usage of facing sand of Kazakhstani content, which ensures high quality of the cast surface.

The results of preliminary research of the influence of graphite inclusions on the properties of cast iron have been presented. The trend of antifriction properties improvement of the cast iron is formation of the graphite phase with established parameters. Control of the graphitization process is possible by means of composition adjustment, as well as cooling conditions. It has been determined, that when size of the graphite inclusions corresponds to pgd45 and pgd90, the cast iron has an optimal slip coefficient, on retention of hardness in accordance with a state standard.

An informational analysis of 44 sources (publications have been analyzed, which are not earlier than 2015, including English language ones) has been made. The made information analysis has shown, that a shape, distribution and size of the graphite inclusions definitely determine properties of the cast iron, such as tribological and antifriction properties. The antifriction properties depend on a chemical composition of the cast iron and some external parameters, such as pouring temperature. Thus, adjusting the composition of the cast iron with certain alloying elements or their ratio, it is possible to regulate the graphite phase and its characteristics and, thus, to influence on the antifriction properties of alloy.

Initiative research of influence of the graphite phase characteristics and some properties of the alloy (slip coefficient and hardness) has been made.

The main method of making the cast products is casting in the green sand molds, according to the results of the foundry production analysis in Kazakhstan. In spite of the relatively high percent of casting defect in the green sand molds, this method has a number of advantages: simplicity of form making, their low cost, a possibility of usage for the widest range of the cast products, etc.

|

|

|

Figure – Casting methods, used in the manufacture of parts of the dredge pumps |

|

|

|

|

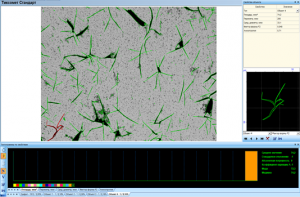

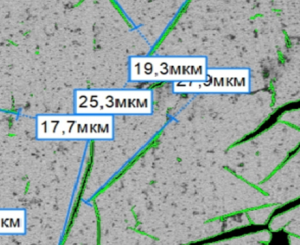

| а – analysis of the graphite inclusions’ form |

b – analysis of the graphite inclusions’ length Figure – example of the Thixomet Pro usage |

Research group

| 1 Shcherbakova Elena Petrovna | research adviser, PhD, acting associate professor of the Nanotechnology and Metallurgy Department

ORCID 0000-0001-6678-6673 Researcher ID N-5639-2017 Scopus Author ID 55543103900 |

| 2 Dostaeva Ardak Mukhamedievna | PhD, acting associate professor of the Nanotechnology and Metallurgy Department

ORCID 0000 -0002-1982-2368 Researcher ID AAB-9478-2020 Scopus Author ID 57160297400 |

| 3 Issagulova Diana Aristotelevna | PhD, associate professor of the Nanotechnology and Metallurgy Department

Scopus Author ID 55778253200 |

| 4 Adamova Gulden Khassenovna | doctoral student of the group “METD-21-1” of the Nanotechnology and Metallurgy Department |

| 5 Kovaleva Tatiana Viktorovna | doctoral student of the group “METD-19-1” of the Nanotechnology and Metallurgy Department

Scopus Author ID 57211297553 |

| 6 Aubakirov Dastan Rakhmetollaevich | doctoral student of the group “METD-19-1” of the Nanotechnology and Metallurgy Department

ORCID 0000-0003-4193-5956 Researcher ID X-1767-2019 Scopus Author ID 57194209750 |

| 7 Kuvardina Akerke Amankulқyzy | graduate student of the group “METM-20-1” of the Nanotechnology and Metallurgy Department |

List of publications

1 Shcherbakova E.P., Dostaeva A.M., Kvon Sv. S., Tyrtykaeva K.T. Analysis of the world trends of production of the dredge pumps’ parts // Scientific papers of the university, Karaganda: Publishing house of KTU. – 2021. – No. 3. – P. 82-86.

2 Shcherbakova E.P., Kvon Sv.S. Influence of the parameters of graphite inclusions on the properties of cast iron // Proceedings of the International Scientific and Practical Conference “Integration of Science, Education and Production – a basis for Implementation of the Plan of Nation” (Saginov readings No. 13) (June 17-18, 2021) – Karaganda, 2021. P. 1363-1364.

3 Shcherbakova E.P. Comparative analysis of the casting technologies of the Republic of Kazakhstan for selection of method // Proceedings of the International Scientific and Practical Conference “Integration of Science, Education and Production – a basis for Implementation of the Plan of Nation” (Saginov readings No. 13) (June 17-18, 2021) – Karaganda, 2021. P. 1365-1366.

4 Shcherbakova E.P., Kovaleva T.V., Arinova S.K., Adamova G.Kh. Influence of the ultrasonic treatment of melt on mechanical properties of the antifriction cast iron AChS-2 // Foundry production, Moscow: Publishing house “Foundry production”. – 2021. – No. 9. – P. 5-7.

Information for potential consumers

The obtained results can be realized in other casting technologies, used in the development of new alloys, in the development of new modes of casting and melting. The obtained theoretical and practical results will be used in industry, engineering calculations and for educational purposes.

AP09058352 “Development and introduction of the new heat-resistant alloy and manufacturing technology of the parts for metallurgical production on its basis”. Project manager Arinova S.K.

Relevance

The topicality of this topic is premised on the need to search for new compositions of the heat-resistant steel, which are optimal in terms of price/quality. In other words, it is necessary to increase the heat resistance of existing and currently used heat-resistant steel with minimum increase of their prime cost. The problem is worsened by the fact that production of the heat-resistant steel is not almost organized in the Republic of Kazakhstan. Therefore, a developed alloy should not have a very complex composition, so that a technology of its production and cast products, made from it, can be adapted and introduced at the operating enterprises of the Republic of Kazakhstan, taking into account a level of the fixed assets development.

The project purpose

Creation of the new improved heat-resistant alloys, as well as parts manufacturing technologies on their basis, taking into account the existing fixed assets on the territory of the Republic of Kazakhstan (Karaganda region).

Expected and achieved results

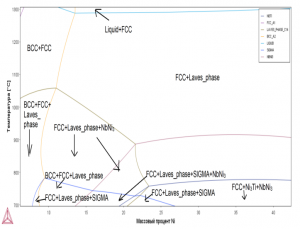

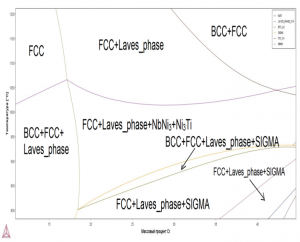

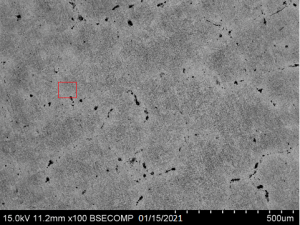

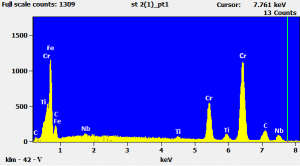

Thermodynamic modeling has been carried out and phase diagrams of the studied system, based on the alloying elements – iron-chromium-nickel, have been made in the program “Thermo-Calc”, based on the result of which, concentration limits of the base of studied system and alloying elements have been defined and a possible phase composition has been found. It has been determined, that evolution of the microstructure occurs during the operation of heat-resistant steels with transformation of the carbide phase and formation of the G – phase, which negatively impacts on heat resistance. However, a balanced composition of the alloy enables to suppress formation of the undesirable phases and predict a process of the microstructure evolution. A new composition of the heat-resistant steel, based on the Fe-Cr-Ni system with additional Nb alloying has been proposed, based on the results of the analysis. Experimental research of melting an alloy of the proposed composition in the laboratory conditions has been conducted and testing its properties has been executed. The obtained results have shown that a chosen direction of improvement of the heat-resistant properties is promising.

|

|

Polythermal sectional views of the Fe-Cr-Ni system’s state diagram

Structure of the alloy, which is tested

Research group

| 1. Arinova Sania Kaskataevna | research adviser, PhD, teacher of the Nanotechnology and Metallurgy Department

Scopus Author ID 57192206332 |

| 2. Aubakirov Dastan Rakhmetollaevich | senior teacher of the Nanotechnology and Metallurgy Department

ORCID 0000-0003-4193-5956 Researcher ID X-1767-2019 Scopus ID 57194209750 |

| 3. Dostaeva Ardak Mukhamedievna | PhD, senior teacher of the Nanotechnology and Metallurgy Department

ORCID 0000-0002-1982-2368 Researcher ID AAB-9478-2020 Scopus Author ID 57160297400 |

| 4. Kovaleva Tatiana Viktorovna | master, doctoral student of the Nanotechnology and Metallurgy Department

Scopus ID 57211297553

|

List of publications

- Issagulov A.Z., Kulikov V.Yu., Kvon Sv.S., Ibatov M.K., Shcherbakova E.P. Studying properties of chrome cast irons modified with titanium carbide // Metallurgy, 60 (3-4), 2021, 299-302

Information for potential consumers

The obtained scientific results can be applied in the development of new production and areas of metallurgical and foundry production.