AP09562489 “Development of the production technology of shaped casting on the basis of step-by-step IT management in order to improve the quality of finished products”. Project manager Issagulova D.A.

Relevance

Automation and digitalization of the work processes of metallurgical production is in an embryonic state in the country’s industry. These processes are very necessary to increase productivity and reduce prime cost of the output products. Development of the production technology of shaped castings, using software, is applied to each of technological processes of the cast billets manufacture, taking into account specific features of the particular production in the region that will significantly improve quality and volume of the cast products, manufactured in the foundry shops.

The project purpose

Development and introduction of the parts’ production technology of mining equipment, made from chrome cast iron with an optimal set of properties, depending on operation conditions of the parts, which will increase a life cycle by 1.5-2 times.

Expected and achieved results

A database of the technical and economic indicators of the preparatory processes has been created. Having considered various methods of casting for modernization of the lost foam casting technology, it ensures stable quality of casting, ensures small size of plant. The introduction of this technology will enable to produce steel, iron and non-ferrous cast products of any brands; to increase an usage ratio of metal up to 0.90 – 0.98; to manufacture the cast products, which weight is from several grams to several tons; to reduce production areas by 3 – 4 times; to reduce costs of the output products by 25 – 50%; to reduce consumption of the burden materials and ferroalloys by 20 – 30%.

|

|

|

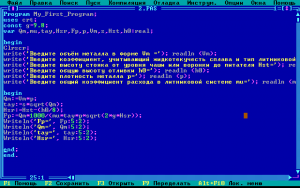

Calculation program of the feed system |

|

Research group

- Issagulova Diana Aristotelevna – research adviser, PhD, associate professor of the Nanotechnology and Metallurgy Department

Scopus ID 55778253200

- Bukanov Zhanat Umirtaevich – responsible person, senior teacher of the Nanotechnology and Metallurgy Department

ORCID 0000-0001-6652-3654

- Arinova Sania Kaskataevna – PhD, teacher of the Nanotechnology and Metallurgy Department

Scopus Author ID 57192206332

List of publications:

- Arinova S.K., Issagulova D.A., Bukanov Zh.U. Creation of the database of technical and economic indicators of the foundry production // CIS Iron and Steel Review, Moscow. Ore & Metals Publishing House – 2021 (IF Scopus 0.953, Web of Science Quartile – Q1, Scopus percentile – 74th).

- Issagulova D.A., Arinova S.K., Bukanov Zh.U. Development of the production technology of shaped casting on the basis of step-by-step IT management in order to improve the quality of finished products // Monograph. Publishing house “Idyll”, 2021. 57 p. ISBN 978-601-355-013-8.

- Patent application: Arinova S.K., Issagulova D.A., Bukanov Zh.U. and others. Method of the shaped castings manufacture on the basis of step-by-step IT-management // Patent application of the Republic of Kazakhstan No. 2021/0788.2, dated 11.08.2021.

Information for potential consumers

The obtained scientific results can be applied to optimize technological cycles of the foundry production.

AP09562116 “Development of structures of the test model’s units of small wind power station with a swinging wind-driven operating element”. Project manager Sholanov K.S.

Relevance

Existing turbine wind power stations can effectively operate in the places, where there is a steady wind direction at a wind speed of about 10 m/s. Average wind speed is 3 m/s in the vast territories of Kazakhstan, a direction and speed of the wind varies in a wide range, in the short periods of time. Wind-driven electric power stations are particularly intended for such regions, as independent energy sources for population of the districts, which are far from the electrical power networks of areas, individual and peasant household, for small manufacturing enterprises.

The project purpose

Research, development and manufacture of the experimental structure of parallel manipulator’s units for the wind-driven electric power station.

Expected and achieved results

A modified dynamic model of the operating element of the wind-driven electric power station has been created; it is substantiated a structure, parameters and design of such units of the manipulating transducer as actuators with a damping system and a power take-off system; test models of these units have been made for the wind-driven electric power stations, which power is 0.5 kW. The results of the works do not have analogues in the world.

|

|

| Test model of the actuator “MP” | Testing stand for a wind power station |

Research group

- Sholanov Korganbai Sagnaevich – research adviser, D.Eng.Sc., professor of the Department of Manufacturing Processes Automation

Scopus Author ID: 56258478400

ORCID 0000-0002-2077-7883

- Omarov Anuar Serikovich – responsible person, doctoral student of the group “EE-19D” of the Department of Manufacturing Processes Automation

ORCID 0000-0001-9602-2770

- Mirzabaev Berik Islambekovich – doctoral student of the group “EE-18D” of the Department of Manufacturing Processes Automation

List of publications

- Korganbay Sholanov, Berik Mirzabayev, Marco Ceccarelli. Expansibility of the Electric Power Production by Wind-driven Electric Power Stations / International Journal of Mechanics and Control. -ISSN: 1590-8844. Accepted for printing.

- K.S. Sholanov. Parallel Manipulator of Robots. 2021 / ISBN 2211-09884, Springer.

- K.S. Sholanov. Bases of industrial robots designing. Textbook / ISBN 978-601-320-435-2, Karaganda, Publishing house of KTU, 2021.

- Sholanov K.S., Omarov A.S. Upgraded wind power station with an umbrella-type sail. 2021 / 0233.1, patent application.

Information for potential consumers

The field of application of the results is renewable energy, creation of the new types of wind power stations.

AP09562369 “Prediction of the states of electrical facilities of the megacities’ heat supply systems as objects of monitoring”. Project manager Feshin B.N.

Relevance

Centralized heat supply systems have a status of the large life support systems for a long time in the infrastructure of Kazakhstan and CIS countries, which relevance of improvement, in the direction of improving quality and energy saving, is one of the high-priority tasks.

Geographic information systems, integrated with software and hardware complexes of the technical systems control (for example, with SCADA systems) are a basis for optimization of the heat supply systems’ operation of megacities.

A totally new approach of solving operation problems, adjustment and prospective activities of the heat supply systems is to integrate existing control resources of the operation modes of megacities’ heat supply systems by means of information technologies.

The project purpose

The project objective is to predict the states of electrical facilities of the megacities’ heat supply systems as objects of monitoring by means of real-time assessment of the vector of observable coordinates X(t), calculating the vector of reference modes and eliminating critical deviations Z(t) = f ((Xe (t) -X ( t)) 2) to improve reliability, to ensure energy saving and minimize reduction of the resource of electromechanical equipment of the pumping stations.

Expected and achieved results

The expected scientific effect is to gain new knowledge in the field of theory and practice of creation of the distributed intelligence systems of control, management and monitoring.

Specialized software has been developed in the MatLAB-Simulink and LabVIEW environments for predicting the resources of rotating machines.

Simulation research of the dynamic modes of high-voltage electrical facilities’ operation of pumping stations has been conducted on the specialized stand of acoustoelectric conversion studying “TMEIC” within the framework of the contract, concluded with LLP “KAZPROM AVTOMATIKA”.

A base of the mathematical models and a base of the simulation research results of dynamic modes of the electrical facilities’ operation of pumping stations have been received.

A draft project of the methodology, assessment and reliability assurance, energy and resource saving of the electromechanical equipment of pumping stations of the megacities’ heat supply systems has been developed.

The obtained results will impact on development of the theory and practice of creating intelligence systems of control, monitoring and management of the distributed multidimensional and multiply-connected industrial facilities, subjected to influence of the external stochastic disturbances.

Specialized stand of acoustoelectric conversion studying “TMEIC” |

Research group

1. Feshin Boris Nikolaevich – research adviser, D.Eng.Sc., professor of the Department of Manufacturing Processes Automation Scopus Author ID 51793548628 ORCID 0000-0002-6444-6429 Researcher ID О-1327-2017 ORCID 0000-0002-6444-6429 2. Kalashnikova Elena Valerievna – responsible person, doctoral student of the group “EE-19D” of the Department of Manufacturing Processes Automation ORCID 0000-0002-3016-444X 3. Tokhmetova Kuralay Muratbekovna – M. Sc. Eng., senior teacher of the Department of Manufacturing Processes Automation ORCID 0000-0003-3685-6153 |

List of publications

- Tokhmetova K.M., Feshin B.N., Bobryakov A.V. “Parameter optimization of the automated electric drive of conveyor of the robotic complex “TRIPOD”” // Scientific papers of the university. No. 1 – 2021 – P. 159-169.

file:///C:/Users/Kuralai/Downloads/29-60c1be0b83cc7371437908.pdf

- Patent application: №2021/1082.2 dated 24.11.2021 “A method of monitoring the prediction of states of the electrical facilities of megacities’ heat supply systems”, authors: Feshin B.N., Kalashnikova E.V., Tokhmetova K.M.

- Kalashnikova E.V., Feshin B.N., Peshko M. “Monitoring high-voltage electric drives of the pumping units of megacities’ heat supply complexes” // 2021 18th International Scientific Technical Conference Alternating Current Electric Drives, ACED 2021 – Proceedings. ISBN 978-166541248-3

https://www.scopus.com/record/display.uri?eid=2-s2.0-85114211854&origin=resultslist

Information for potential consumers

Field of application. The scientific results are applicable to create monitoring systems of the electrical facilities of pumping stations of the heat supply systems in the Republic of Kazakhstan, the Russian Federation and other countries, which have a sharply continental climate.

№AP09562222 “Information and measuring new-generation system, based on the fiber-optic sensors”. Project manager Yugay V.V.

Relevance

Fiber optic equipment and technologies have been actively developing for more than 50 years. The development of this technology has enabled to make telecommunication systems, operating on a completely different principle, when a light pulse is transmitted instead of an electrical signal. This has enabled to increase the transmission capacity of information transfer systems and take them to a new level of development. Creation of the high-speed distributed explosion-proof system of ground pressure measurement, by means of a fiber-optic pressure sensor (FOPS) will enable to increase the safety of mining operations execution in the coal mines, as well as to promptly inform about formation of the dangerous zones of mechanical stress concentration in the arch of mine opening, that results in collapse of its arch. The fiber-optic pressure sensor will enable to ensure high accuracy of the ground pressure control, which affects a structure of the arched support. Control of the ground pressure will allow to timely take measures of strengthening emergency-dangerous places, where destruction of the arch of mine opening is possible. The control of the ground pressure will also allow to choose the most rational chart of supports, that will significantly save material resources.

The project purpose

Development of the test model of information and measuring new-generation system, based on the energetically passive fiber-optic sensors for introduction into the industrial enterprises of the Republic of Kazakhstan.

Expected and achieved results

– development of the adequate mathematical and computer models of automated monitoring system of the industrial facilities’ technical condition, based on the fiber-optic sensors and intelligent sensor networks. (Industry 4.0).

– development of the hardware and software complexes and control algorithm of the intelligent sensor networks.

– making the test model of the energetically passive fiber-optic sensors.

Laboratory model of the information and measuring new-generation system, based on the energetically passive fiber-optic sensors |

Research group

1. Yugay Vyacheslav Viktorovich – research adviser, PhD, head of the Technology and Communication System Department ORCID iD 0000-0002-7249-2345 Scopus Author ID 8379849200, WoS Researcher ID ABA-7820-2020) 2. Kaliaskarov Nurbol Baltabaevich – responsible person, master, senior teacher of the Technology and Communication System Department ORCID iD 0000-0003-3684-1488 Scopus Author ID – 57201113007 3. Alkina Aliya Dauletkhanovna, master of Infocommunications ORCID iD 0000-0003-4879-0593 Scopus Author ID – 57160184600 |

List of publications

- V. Yugay, A. D. Mekhtiyev, S. G. Ozhigin, R. ZH. Aimagambetova, Y. G. Neshina, Y. ZH. Sarsikeyev Using optical fibers to control the stress-strain state of steel structures, subjected to a fatigue failure //Metallurgy 61 (2022) 2, 351-354.

- Yugay V.V., Mekhtiyev A.D., Alkina A.D., Kaliaskarov N.B. Measuring results of the mechanical stresses and deformations of metal surfaces, by means of optical fibers / copyright certificate No. 20183, dated September 9, 2021.

- Yugay V.V., Alkina A.D., Kaliaskarov N.B., Mekhtiyev A.D. Measurement of the mechanical stresses and deformations of metal surfaces, by means of optical fibers // Topical problems of our time No. 3(33), 185-189.

Information for potential consumers

The information and measuring system, based on the fiber-optic sensors enables to take measurements in the environments, which are dangerous, in terms of gas and dust, to make measurements, registration in the long-distance areas and in the hard-to-reach places. Adaptation to various tasks is possible.

Field of application: mining industry, metallurgy, construction.

AP09562666 “Development of the control system of heat energy distribution in the heat supply systems, on the base of digital model”. Project manager Tomilova N.I.

Relevance

The main factors, motivating the full-scale digitalization of power supply systems on a global scale are: energy resources saving, assurance of safe, reliable and economical mode of energy systems’ operation, reduction of hazardous environmental emissions, improvement and stabilization of the ecological situation on the planet.

A modern stage of development of the heat supply systems of the Republic of Kazakhstan is characterized by growth of demand for energy and information resources due to intensive technical, technological and informational re-equipment of all spheres of the country’s economy (laws “On Electrical Power Engineering”, “On Energy Saving”, “Informational Kazakhstan – 2020”, “Informational Kazakhstan – 2030”, the state program “Digital Kazakhstan” and many government decrees).

The project purpose

Increasing the efficiency of usage and transportation of heat energy of the heat supply system by means of developing a control system of the transmission and distribution of heat energy, based on a change of the transmission capacity of heat network, using a digital model.

Expected and achieved results

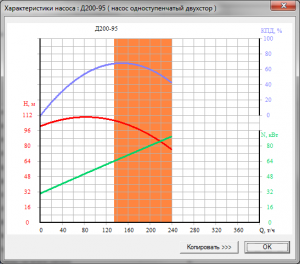

The main stages of work: development and realization of the calculation subsystems of optimal thermohydraulic modes of the transmission and distribution of heat network’s heat energy, assessment of the heat network’s transmission capacity, as per the main parameters, control of the transmission and distribution of heat energy by means of increasing the transmission capacity of heat network’s heat pipelines.

The results of the work and their novelty: a control system of the heat energy distribution, based on the digital model has been developed and realized, which is an integrator of the automated work places, services and subdivisions of the heat supply system, operating in the common information space.

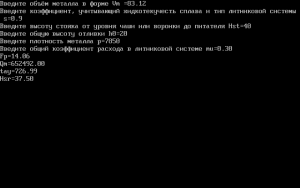

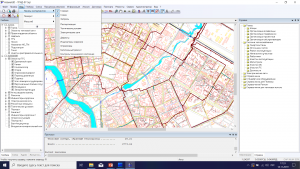

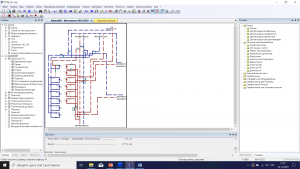

|

|

|

|

User interface of the control system of heat energy distribution in the heat supply systems, based on the digital model

Research group 1. Tomilova Nadezhda Ivanovna, Cand. Eng.Sc., associate professor of the Department of Information Computer System Scopus Autor ID 7194212148 ORCID 0000-0001-8782-5627 Researcher ID B-2794-2019 2. Tomilov Alexander Nikolaevich, Ph.D, head of laboratory of the Department of Information Computer System Scopus Autor ID 57201117035 ORCID 0000-0002-0491-1640 3. Iskakov Mukhamedalim, Cand. Eng.Sc., associate professor of the Department of Information Computer System |

|

List of publications

- Tomilova N.I., Tomilov A.N. Information model of the control system of heat energy distribution in the heat supply systems. Proceedings of the International Research and Practice Conference “Integration of science, education and production – a basis of realization of the Plan of Nation” (Saginov readings No. 13). – Karaganda: KTU, 2021. – P. 970 – 972.

- Tomilova N.I., Tomilov A.N. Information models of the control objects of heat supply systems. A scientific work // Certificate of entering information about rights to an object into the national register, protected by copyright: RK, August 11, 2021. – No. 19720. -2 p.

- Tomilova N.I., Tomilov A.N. Conditions of the technological admissibility of thermohydraulic modes of the centralized heat supply systems. A scientific work // Certificate of entering information about rights to an object into the national register, protected by copyright: RK, August 11, 2021. – No. 19721. – 2 p.

- Tomilova N.I. Information models of the control objects of heat supply systems: Monograph. – Karaganda: SANAT- Printing, 2021. – 112 p.

- Tomilova N.I., Tomilov A.N. and etc. Digital models of stabilizing the hydraulic mode of heat supply systems // Journal of Theoretical and Applied Information Technology. – Islamabad: FCE, 2021. At the stage of publishing.

- Tomilova N.I., Rybachuk Yu.M., Golovacheva V.N. Digital modeling of stationary modes of the heat supply systems, based on inverse characteristics // Bulletin of the National Academy of Engineering of the Republic of Kazakhstan: Republican Public Association, 2021. – No. 4. At the stage of publishing.

- Iskakov M.B., Tomilov A.N. Formalization of the task of analyzing stationary modes of the complex heat supply systems // Bulletin of the National Academy of Engineering of the Republic of Kazakhstan: Republican Public Association, 2021. – No. 4. At the stage of publishing.

Information for potential consumers

Software components of the system are ready for industrial introduction by 100%.

Field of application

Energy systems, providing the services of transmission and distribution of the heat energy for consumers of the industrial centers and settlements of the Republic of Kazakhstan; higher educational institutions, which train IT specialists and heat power engineering specialists.