AP08856371 “Developing a resource-saving technology for repairing long rods of hydraulic cylinders of large-sized special equipment for industrial use with the possibility of restoring local damage at the place of its operation”, p.m. Zhetessova G.S.

Relevance

At present, it is common practice to produce rods with galvanic chromium coating (GCP) for hydraulic cylinders of large-sized special equipment for industrial use. It provides wear resistance, anti-corrosion properties, reduced friction coefficients, and resistance to chemical and thermal effects of the environment. The need to use protective coatings is caused by high loads and severe operating conditions of the equipment. However, when repairing the inevitable local damage to the surface of the rods, it is possible to achieve the original characteristics of the product only by completely re-chromizing the surface, the cost of which can reach 70% of the cost of the product. The idea of this project is to develop a cheaper alternative technology for repairing long, large-sized rods over the entire surface, as well as with the subsequent elimination of local damage based on thermal spraying processes. This will make it possible to carry out repair work at the site of equipment operation with obtaining a wear-resistant coating that is not inferior in its properties to GHP.

Project purpose

The development of a technology for repairing damage to the chrome-plated surface of hydraulic cylinders long rods of large-sized special equipment for industrial use based on thermal spraying methods, which will be a cheap, environmentally friendly alternative to the process of re-chrome plating and will provide better properties of the restored surface compared to other repair technologies used today, and will also give the possibility of carrying out repairs on site.

Results achieved

A full-size prototype of the thermal spray installation was developed and the technology was tested was tested at the factory. An Act of industrial testing and an Act of implementation were received, indicating recommendations for introducing the technology in the conditions of the Karaganda branch of the Limited Liability Partnership “Hanza-Flex Hydraulic Almaty”. Within 2022, the following tasks were implemented:

– additional analysis of the data and classification of damage to the surface of the rods was carried out;

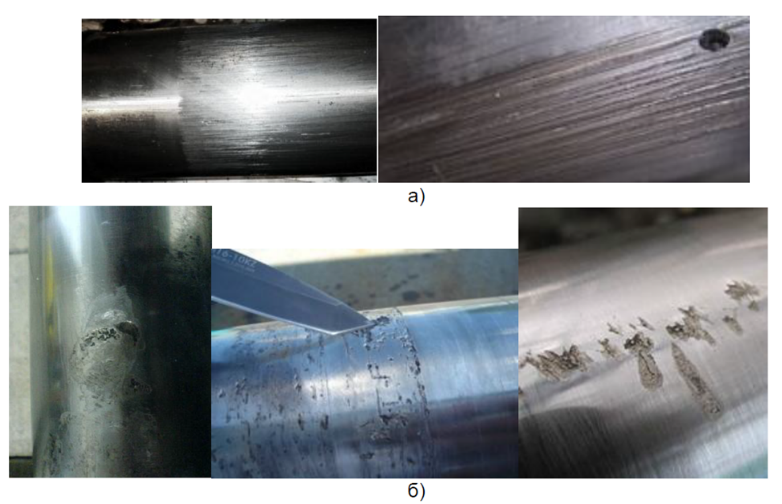

– there was developed a technique of preparing the substrate before local restoration of the surface, taking into account the nature of the damage and the features of the spraying process;

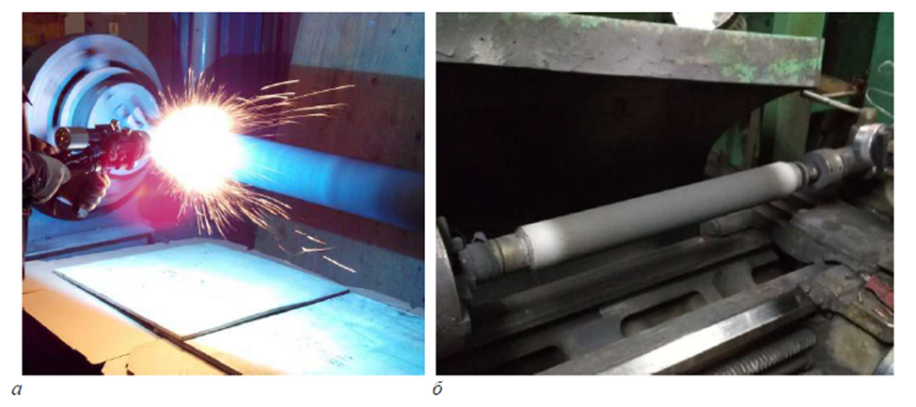

– a technique was developed and the parameters of local coating deposition were selected taking into account the nature and size of typical damages;

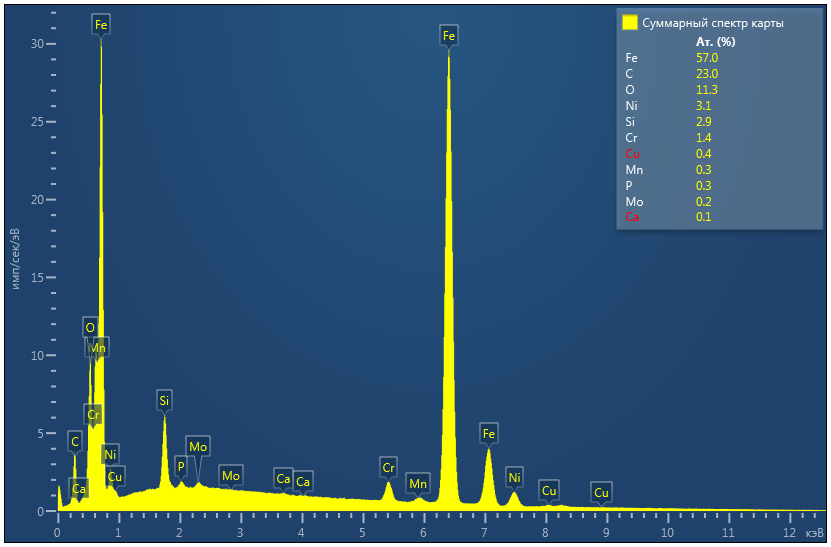

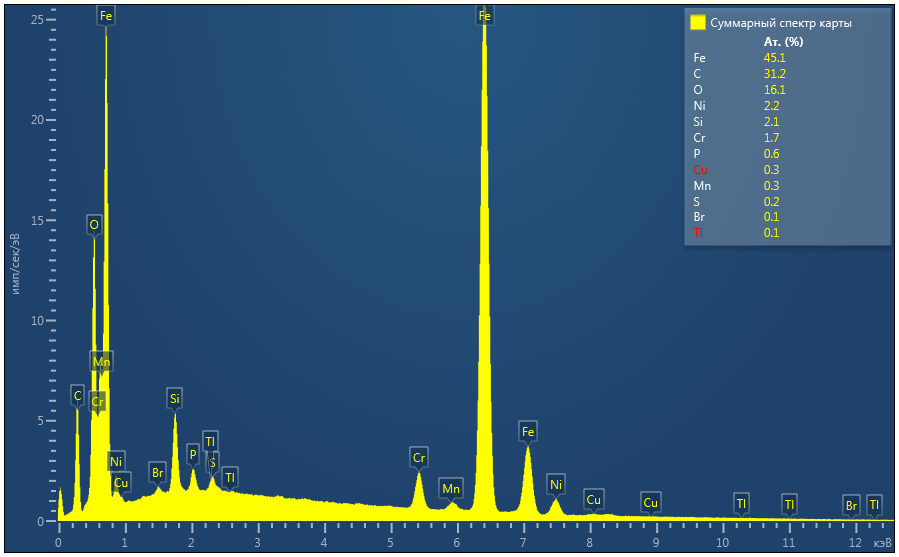

– experiments on local deposition of coatings and studies of the properties of the obtained layers were carried out;

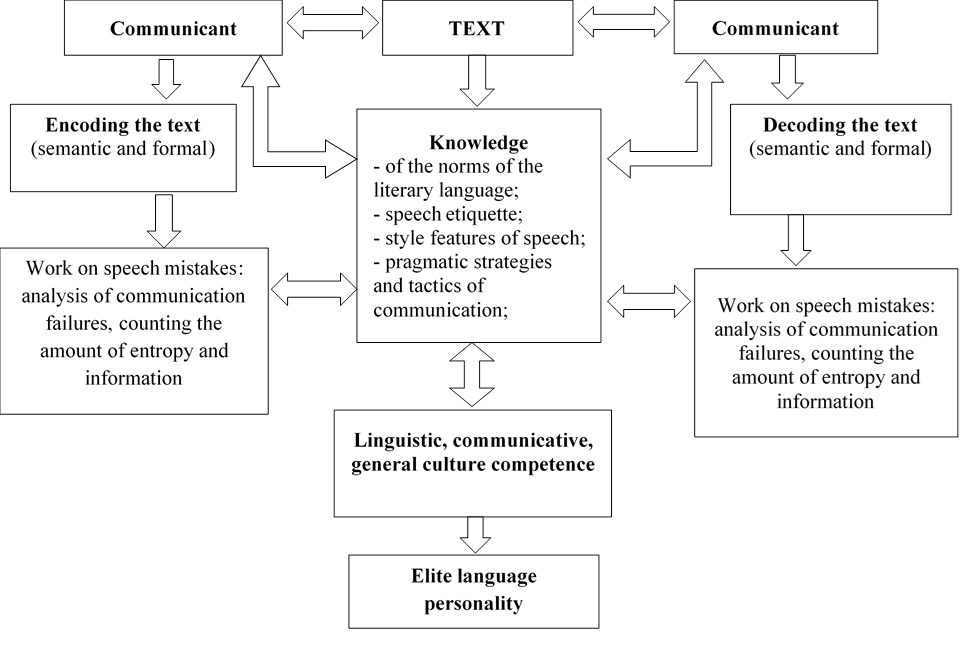

– there was designed and tested a prototype of a setup for restoration of the rod surface;

– taking into account the inaccuracies received, the prototype was modernized.

The methodology of scientific research applied by the project participants, as well as availability of a good material and technical base, allows speaking about reliability of the project results.

The work performed in the course of the project implementation was carried out in full and at a sufficiently high level. First of all, this is caused by the high competence of the scientific team of the project authors, the methodology of scientific research they use, as well as availability of a good material and technical base.

The novelty of technical solutions is confirmed by a patent for an invention of the Republic of Kazakhstan No. 35873 dated September 30, 2022, a utility model patent No. 6901 dated October 19, 2021, a certificate of registration of rights to an intellectual property object No. 27846 dated July 15, 2022, an Industrial Testing Act dated 30/07/2022, Act of Implementation dated 29/09/2022 indicating recommendations for implementation of the technology in the conditions of the Karaganda branch of the Limited Liability Partnership “Hanza-Flex Hydraulic Almaty”.

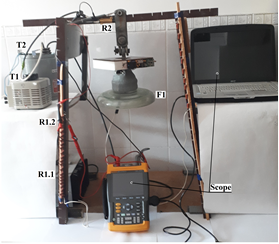

In the course of the research work, an experimental prototype of thermal spraying was developed and installed, on which experimental spraying on samples was carried out.

As a result of the experiments, the main conclusions were drawn regarding the performance of the prototype setup in accordance with the technological parameters. As a result, the main design flaws were identified, namely, low rigidity and a small deflection of the structure within the permissible limits, which were subsequently eliminated using the results of computer modeling and improving the design by pulling an additional cable through the aluminum profile of the guides.

|

|

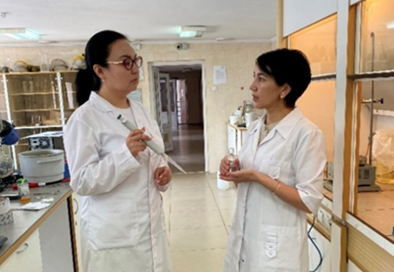

| Figure 1 – Types of wear occurring on the rod surface:

а) scrapes and scratches; b) rubmarks, galvanic chrome layer destruction |

Figure 2 – Spraying setup |

|

|

| Figure 3 – Shot blasting process of hydraulic cylinder rod surface | Figure 4 – Coating spraying (a) and rod after spraying (b)

|

Research team

- Zhetessova Gulnara Santayevna – project manager, Doctor of Engineering, Professor of the TEMES Department. ORCID 0000-0001-6504-3405

Researcher ID S-3369-2017

Scopus Author ID 57212376967

- Ibatov Marat Kenesovich – scientific consultant, Doctor of Engineering, Professor of . TT&LS Department

ORCID ID 0000-0001-5062-7790

ResearcherID N-9320-2017

Scopus Author ID 57189211438

- Olegas Černašėjus – scientific consultant, PhD, Acting Professor of the “Engineering of Mechanics and Materials” Department, Vilnius Technical Universityn.a. Gediminas

Scopus Author ID 22978289800, ORCID ID 0000-0003-2196-6392

- Jelena Škamat- scientific consultant, Doctor of Engineering, senior researcher of the Laboratory of Composite Materials, Associate Professor, the “Mechanics and Engineering of Materials” Department, Vilnius Technical University n.a. Gediminas

ORCID ID 0000-0002-4441-6839

Scopus Author ID 36338084700

Web of Science Researcher ID AAR-4325-2020

- Nikonova Tatyana Yurievna – principal investigator, Ph.D., Acting Associate Professor of the TEMES Department

ORCID 0000-0002-6539-1263

Scopus Author ID 57202087837

- Yurchenko Vasily Viktorovich – PhD, Acting Associate Professor, head of the TEMES Department

ORCID 0000-0002-6543-1632

Scopus Author ID 57213756780

- Zharkevich Olga Mikhailovna – PhD, Acting Professor of the TEMES Department

ORCID 0000-0002-4249-4710

Scopus Author ID 55339344600

- Morozov Petr Yurievich – MT, hydraulic engineer of the Karaganda branch of Hanza-Flex Hydraulic Almaty LLP

List of publications for 2022

- Zhetessova G., Nikonova T., Gierz Ł., Berg A., Yurchenko V., Zharkevich O., Kalinin A. Comparative analysis of the dynamic strength Properties of the long guides of intelligent machines for a new method of the thermal spraying of polymer concrete. Appl.Sci. 2022, 12, 10376. https://doi.org/10.3390/app122010376

- Zhetessova G., Nikonova T., Gierz Ł., Zhunuspekov D.,Yurchenko V., Zharkevich O. Preparation of the Surface of Long-Dimensional Rods of Hydro-Cylinders for Thermal Spraying Using an Abrasive Jet. Coatings 2022, 12, 1514. https:// doi.org/10.3390/coatings12101514

- Practical recommendations in preparation for the process of applying coatings by thermal spraying of long rods / Zhetessova G.S., Nikonova T.Yu., Yurchenko V.V., Zhunuspekov D.S., Deshko T.A. // University Proceedings. No. 3, 2022, pp. 61-67

- Development of a technology for the repair and restoration of long rods using thermal spraying methods: Monograph / Zhetessova G.S., Škamat Je., Černašėjus O., Nikonova T.Yu, Zharkevich O.M., Yurchenko V.V., Khrustaleva I.N., Zhunuspekov D.S. SPb.: POLYTECH-PRESS, 2022. – 99 p.

- Development of a technology for the repair and restoration of long rods using thermal spraying methods: monograph / Zhetessova G.S., Nikonova T.Yu., Zharkevich O.M. Monograph, Karaganda: Karaganda Technical University named after Abylkas Saginov, 2022. 108 p. ISBN 978-601-355-045-9

- Nikonova T.Yu., Zhunuspekov D.S. Studying the factors influencing the formation of cracks in steels. // Proceedings of the International Scientific and Practical Conference “Integration of Science, Education and Production – the Basis for the Implementation of the Plan of the Nation” (Saginov Readings No. 14), June 16-17, 2022. In 2 parts. – P.248-250

- Patent for an invention of the Republic of Kazakhstan No. 35873 “Angled scraper conveyor” by Zhetessova G.S., Nikonova T.Yu., Zharkevich O.M., Yurchenko V.V., Beisembaeva K.M., Zhakenova S.A. et al. Bulletin No. 39 of 09/30/2022.

- Certificate of registration of rights to the object of intellectual property No. 27846 dated July 15, 2022 “Calculation of technological parameters of coating during gas thermal processing” authors Zhetessova G.S., Nikonova T.Yu., Yurchenko V.V., Zharkevich O.M. et al.

Information for potential consumers

Application area: The target consumers of the obtained results of the project can be machine-building enterprises, mechanical parks of large and medium enterprises in the mining industry, repair and service enterprises, manufacturers of hydraulic equipment.

АР08856344 “Developing a complex for remote monitoring of the structural elements state of high-voltage transmission lines during operation based on intelligent noise-immune telemetry systems”, p.m. V.V. Yugay

Relevance

Developing methods of current control of volumetric and surface leakage currents of strings of high-voltage insulators during operation that allow developing predictive models of the state of their insulation is an urgent scientific and technical task. Its solution will make it possible to make informed, timely decisions on the replacement of insulators with low performance characteristics during the period of routine maintenance, which will reduce power losses.

Project purpose

Reducing losses and accidents during the transportation of electricity on overhead high-voltage power lines (HVPL) with voltage above 110 kV based on interrelated scientific and technical solutions containing the concept, principles of construction and design of a complex for remote monitoring of the state of structural elements of high-voltage overhead power lines during their operation based on intelligent diagnostic noise-immune telemetry systems.

Results achieved

The expected economic effect is to reduce the technical and technological losses of electricity at high-voltage transmission lines, reduce the cost of electricity transportation and increase its reliability.

Methods of current monitoring of bulk and surface leakage currents of high-voltage insulators were developed and described.

The analysis of electrical energy converters necessary for the implementation of the project tasks was carried out.

There was developed and described the structure of the hardware of electrical energy converters for autonomous power sources of monitoring systems.

|

|

| Laboratory bench for experimental studies of leakage currents in suspension insulators | Presentation of the grant results at the enterprise of Corporate University

KAZPROAVTOMATIKA LLP |

Research team

- Yugay Vyacheslav Viktorovich – project manager, PhD, head of the APP Department

Scopus Author ID: 8379849200

ORCID 0000-0002-7249-2345

- Kaverin Vladimir Viktorovich – principal investigator, PhD, Associate Professor of the APP Department

ORCID 0000-0003-2021-7445

Scopus Author ID 57214729792

- Voytkevich Sofya Valentinovna – PhD, Acting Associate Professor of the APP Department

ORCID 0000-0003-4267-3468

Scopus Author ID 57191158205

- Kalinin Alexey Anatolyevich – PhD, Acting Head of the ICS Department

ORCID 0000-0003-4699-7240

Scopus Author ID 57193550259

- Em Gennady Arkadievich – MT, sn. lecturer of the APP Department

ORCID 0000-0003-2639-0492

- Ivanov Valery Anatolyevich – MT, sn. lecturer of the APP Department

ORCID 0000-0003-2811-7908

Scopus Author ID 57195273869

- Levin Igor Vitalyevich – Chairman of PC “Progress-Service”

Scopus Author ID 57195285510

- Yezhebayeva Sholpan Yesengeldiyevna – doctoral student, gr. EE-19D of the APP Department

ORCID 0000-0001-5925-1646

- Sayfulin Ruslan Faritovich – doctoral student, gr. EE-18D of the APP Department

ORCID 0000-0003-2610-9525

СList of publications for 2022

- Kaverin, D. Abisheva, G. Em, A. Kalinin, V. Yugay // Studying Partial Discharge Currents of High Voltage Power Line Suspension Insulators // International Journal on Energy Conversion, 2022, Vol 10, No. 3, Pages 88-96. Energy Category-Engineering and Power Technology, процентиль – 56. ISSN 2281-5295 DOI: https://doi.org/10.15866/ irecon.v10i3.21769

- Kaverin V., Abisheva D., Em G., Kalinin A., Yugay V. // Study of partial discharges of suspension insulators of high-voltage power lines Lines // International Journal on Energy Conversion, 2021, 9(6), Pages 88-96. Energy Category-Engineering and Power Technology, процентиль – 56. DOI https://doi.org/15866/irecon.v9i6.21083

- Patent No. 35701 dated April 22, 2021. Breido I.V., Kaverin V.V., Voitkevich S.V. The method of automatic remote telemetry in the electric power industry.

Information for potential consumers

Application area: Enterprises operating high-voltage overhead power lines; enterprises of the mining and metallurgical industry, enterprises generating electricity, enterprises designing high-voltage overhead power lines.

AP08855477 “Developing and implementing the technology of producing Nihard class cast iron with improved performance properties for parts of mining and metallurgical equipment”, p.m. Issagulov A.Z.

Relevance

A number of parts for mining and metallurgical equipment are made of Nihard class cast iron (grids, fittings, plates, pump parts, etc.). Despite the significant advantages of using these cast irons, they also have their drawbacks – relatively poor casting properties (low fluidity, high shrinkage), besides, machining in the parts manufacturing using castings is difficult. In this project, it is planned to ensure the required operational and technological properties of Nihard class cast irons in relation to specific parts of mining and processing plants equipment by selecting the state of the metal base, using corrected alloying and modification, using improved crystallization and heat treatment modes. The issue of manufacturing thin-walled and shaped castings will also be resolved.

Project purpose

Developing and implementing the technology of producing parts for mining and metallurgical equipment using Nihard class cast iron with an optimal set of properties, depending on the operating conditions of the parts, which will increase the service life by 1.5-2 times

Results achieved

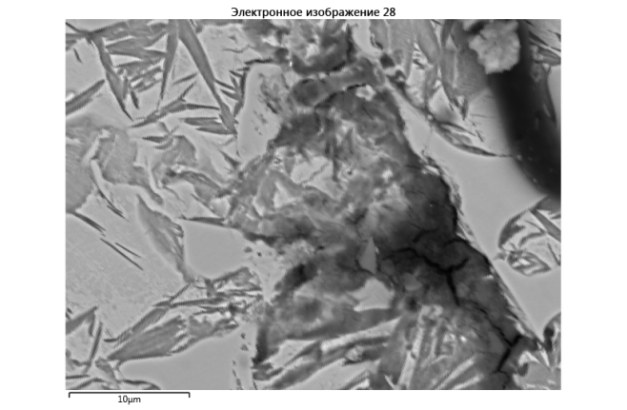

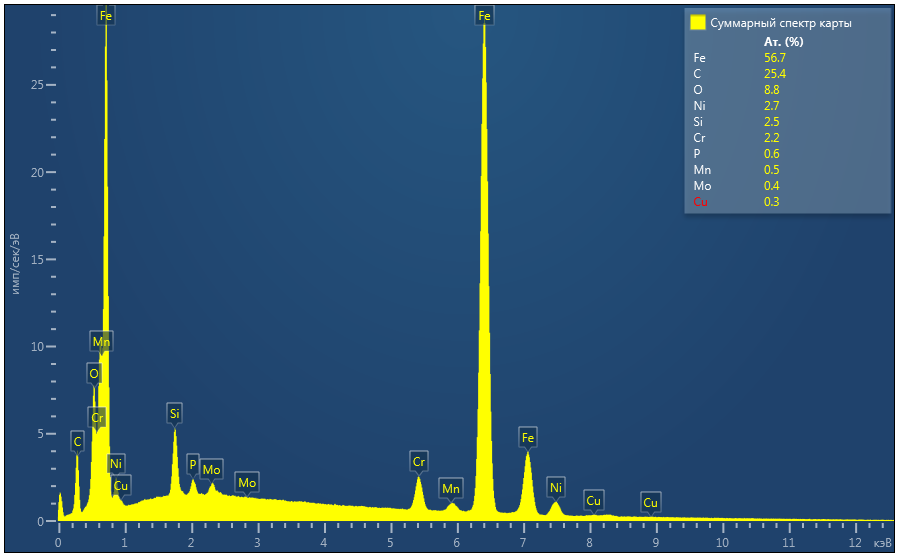

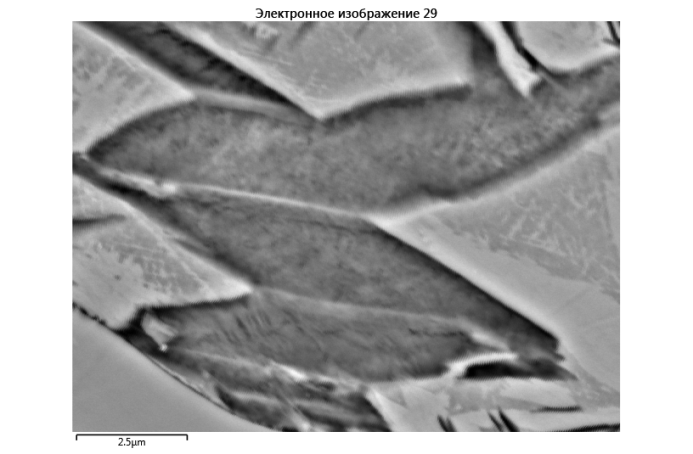

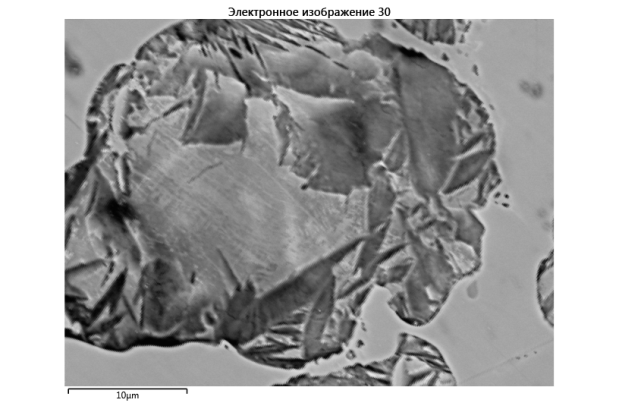

A technology has been developed for manufacturing and machining parts made of Nihard cast iron with enhanced properties for mining and metallurgical equipment. The developed technology consists in smelting cast iron of the Nihard class with an adjusted composition and introduction of titanium carbide for the appearance of a certain amount of free graphite in the structure. The subsequent modification leads to the transformation of a part of the graphite into a spherical shape, which leads to the existence of a mixed structure: an austenite-ledeburite matrix, cementite, and a certain amount of free graphite. The presence of such a structure provides increasing the operational properties by 1, 2 – 1.3 times. The tests were carried out at the production site, the technological glow charts of the process were developed, the acts of implementation tests were received.

As a result of the work carried out, experimental tests and adjustment of the results of manufacturing replaceable parts at the production site were carried out. The tests were carried out at the production site of the Parkhomenko KMZ LLP. The tests carried out showed that as a result of adjusting the composition of cast iron and modifying the mechanical properties of products were improved. Preliminary flow chart No. 22/01-P dated 06/24/2022 and a test certificate dated 27.06.2022 were received at the Parkhomenko KMZ.

|

|

| а | |

|

|

| b | |

|

|

| c | |

Experimental alloy structure: presence of layered (a, b) and spherical (c) graphite, x 5 000

Research team

1 Issagulov Aristotel Zeynullinovich – project manager, Doctor of Engineering, Professor of the NTM Department

ORCID 0000-0003-2174-9072

Researcher ID C-7415-2016

Scopus Author ID 57211295299

2 Vitaly Yurievich Kulikov – principal investigator, PhD, Professor, Acting head of the NTM Department

ORCID 0000-0001-6191-8569

Researcher ID N-5596-2017

Scopus Author ID 56168395900

3 Ibatov Marat Kenessovich – scientific adviser, Doctor of Engineering, Professor of the TT&LS Department

ORCID ID 0000-0001-5062-7790

ResearcherID N-9320-2017

Scopus Author ID 57189211438

4 Kvon Svetlana Sergeevna – PhD, Professor of the NTM Department

ORCID 0000-0002-5439-4426

Researcher ID N-5602-2017

Scopus Author ID 5706189240

5 Shcherbakova Yelena Petrovna – PhD, Acting Associate Professor of the NTM

Department

ORCID 0000-0001-6678-6673

Researcher ID N-5639-2017

Scopus Author ID 55543103900

6 Sultangaziyev R.B. – PhD, Acting Associate Professor of the NTM Department

7 Arinova Saniya Kaskatayevna – PhD, teacher of the NTM Department

Scopus Author ID 57192206332

8 Dospayev Murat Mantenovich – Doctor of Engineering, Chief Researcher of the Chemical and Metallurgical Institute n.a. Zh. Abishev; Republican State Enterprise “National Center for Complex Processing of Mineral Raw Materials of the Republic of Kazakhstan”

Scopus Author ID 57204316546

9 Medvedeva Irina Yevgenievna – sn. lecturer of the NTM Department

Scopus Author ID:57192206637

10 Aubakirov Dastan Rakhmetollaevich – sn. lecturer of the NTM Department

Scopus Author ID: 57194209750

List of publications for 2022

1 Issagulov A.Z., Kulikov V.Yu., Kvon Sv.S. Producing Nihard-class cast irons with high performance properties: Monograph. Germany: LAP LAMBERT, 2022, 55 p. ISBN 978-620-4-74387-5

2 Issagulov A.Z., Kvon S.S., Kulikov V.Yu., Ibatov M.K., Arinova S.K. Chromium-nickel cast iron composition effect on properties and graphitization process // Metalurgija, Croatia: Croatian Metallurgical Society. 2022. No. 1 (61). P. 197-199 (IF Scopus 0.388, Scopus percentile 37h).

3 Aubakirov D.R., Issagulov A.Z., Kvon S.S., Kulikov V.Yu., Arinova S.K. Modifying Effect of a New Boron-Barium Ferroalloy on the Wear Resistance of Low Chromium Cast Iron // Metals, Switzerland: MDPI AG, 2022, 12(7), 1153; https://doi.org/10.3390/met12071153 (Web of science, quartile – Q2)

4 A.Z. Issagulov, Sv.S. Kvon, V.Yu. Kulikov, D.R. Aubakirov, Ye.P. Chsherbakova Studying the chrome-nickel cast iron structure and properties after modification on industrial samples // Metalurgija, Croatia: Croatian Metallurgical Society. 2023. No.1 (62). P. 122-124 (IF Scopus 0,388, Scopus percentile 37).

5 А.А. Аkberdin, A.Z. Issagulov, S.S. Kvon, Y.P. Chsherbakova, D.R. Аubakirov, G.H. Adamova. Modifier effect on mechanical properties of low-chromium cast iron // Metalurgija, Croatia: Croatian Metallurgical Society. 2022. No. 1 (61). P. 159-162 (IF Scopus 0,388, Scopus percentile 37).

Information for potential consumers

The obtained scientific results can be used in the development of new areas of metallurgical and foundry industries, new technological processes of smelting and modes of out-of-furnace and heat treatment of alloys, partially extended to other grades of alloys with special properties.

AP08856688 “Developing methods of natural triterpenoids isolation from plants and their chemical transformation in order to search for new biologically active substances”, p.m. Takibayeva A.T.

Relevance

Natural triterpenoids and their derivatives attract attention of researchers around the world who are looking for new bioactive agents, due to their wide application and synthetic capabilities..

Project purpose

Studying and developing effective methods of isolating natural triterpenoids from domestic plants for subsequent synthesis of new biologically active derivatives based on them.

Results achieved

Betulin derivatives were obtained by reacting it with phenylferrocenyl alcohol, glyoxalic acid and tetramethylglycoluril, dimethyl horphosphate. The synthesis and study of the relationship “structure-bioactivity” of the obtained compounds were carried out.

Methods of obtaining and optimal conditions for the synthesizing triterpenoid derivatives under the conditions of classical synthesis, microwave and ultrasonic activation have been developed; pharmacologically active derivatives of triterpenoids by heterocyclization of hydroxyl-substituted betulin. The physical and chemical and spectral characteristics, the “structure-bioactivity” relationships of the synthesized substances have been studied.

Bioscreening of the new functionally substituted triterpenoids and their derivatives for antioxidant activity, antimicrobial, anti-inflammatory and other types of biological activity was carried out.

A recommendation was received on the introduction of the technology for obtaining betulin from the birch bark Betula kirghisorum by ultrasonic and microwave methods at pharmaceutical enterprises of the Republic of Kazakhstan. The technology of obtaining betulin from birch bark Betula kirghisorum by ultrasonic and microwave methods solves several problems:

- A method of producing betulin from birch bark, including grinding the bark, extracting with alcohol, separating the solution, followed by removing the solvent from it, characterized in that the crushed birch bark is added with butyl alcohol in a ratio of butanol: birch bark 5: 1, while the mixture is additionally treated with ultrasound at temperature 75°C within 6, 16, 26, 36 min.

- The technology of obtaining betulin from the birch bark Betula kirghisorum by ultrasonic and microwave methods differs in that betulin was isolated from this type of birch Betula kirghisorum for the first time.

The method according to claim 1 differs in that the extraction of betulin is carried out by ultrasonic extraction at a power of 300 W, the duration of the process is 26 minutes.

Research team

1 Takibayeva Altynarai Temirbekovna – project manager, PhD, head of the C&CT De[artment

ORCID ID 0000-0003-0536-0817

Scopus Author ID 12808279300

Researcher ID ABA-1648-2020

2 Kassenov Rymkhan Zeinollaevich – principal investigator, Candidate of Chestry, Associate Professor of the “Organic Chemistry and Polymers” Department of NJSC Karaganda University n.a. E.A. Buketov

ORCID ID 0000-0002-9832-5115

Scopus Author ID 56616120800

3 Ibrayev Marat Kirimbaevich – Doctor of Chemistry, Professor of the C&CT Department ORCID ID 0000-0003-0798-5562

Scopus Author ID 6508179234

Researcher ID V-9320-2018

4 Issabayeva Meruert Berdeshevna – Candidate of Chemical Sciences, Associate Professor of the C&CT Department

ORCID ID 0000-0002-7053-8610

Scopus Author ID 14219273700

Scopus Author ID 14831459000

5 Akhmetova Saule Baltabaevna – Candidate of Medicine, Professor-researcher, head of the “Clinical Immunology, Allergology and Microbiology” Department of NJSC Medical University of Karaganda

Scopus Author ID 25030129100

6 Zhumadilov Sayat Sagatovich – doctoral student of NJSC Karaganda University named after E.A. Buketova

ORCID ID 0000-0002-4046-311X

7 Demets Olga Vladimirovna – doctoral student of the Research Institute of Tomsk State University, sn. laboratory assistant of the C&CT Department

ORCID ID 0000-0002-9440-4668

8 Aliyeva Madina Ramankulovna – MT, sn. lecturer at the C&CT Department

ORCID ID 0000-0003-0819-2484

9 Lyapunova Maria Vyacheslavovna – chemist laboratory assistant of the “Organic Synthesis” Research Institute of Tomsk State University

10 Ospanov Bekarys – master student, gr. CTOVM-21-1 of the C&CT Department

List of publications for 2022

- Demets, O.V., Takibayeva, A.T., Kassenov, R.Z., Aliyeva, M.R. Methods of Betulin Extraction from Birch Bark // Molecules 2022, 27 (11), 3621.

- Patent of the Republic of Kazakhstan for a utility model No. 7511 dated 10/14/2021. Takibayeva A.T., Ibrayev M.K., Kassenov R.Z., Demets O.V., Aliyeva M.R. Method of producing 3,28-dimethylphosphate of betulin with antimicrobial activity.

- Fedorishin D.A., Takibayeva A.T., Bakibayev A.A., Demets O.V., Ibrayev M.K., Lyapunova M.V., Aliyeva M.R., Kurzina I.A., Mamaeva E.A., Ukhov A.E., Akhmetova S.B., Kassenov R.Z. Studying Non-rhetorical Composite Biomaterials Based on Betulin and Glycoluryl for the Treatment of Infected Wounds and Burns. Molecules 2022, 27, x. https://doi.org/10.3390/xxxxx.

Information for potential consumers

Application area: Chemistry, medicine and pharmaceutical industry.

Efficient isolation methods have been developed and potentially biologically active derivatives based on betulin have been obtained. Betulin isolated from Betula kirghisorum expands the understanding of the inexhaustible possibilities of chemical transformation of triterpenoids and can be used both for large-scale production of new derivatives and chemical synthesis based on it.

AP08856918 “Developing linguistic mathematical aggregated model of specialists’ speech diagnostics based on the methods of theory of the language structure self-organization”, p.m. Ospanpva B.R.

Relevance

The relevance of the project lies in the possibility of using a linguo-mathematical aggregated model of speech diagnostics to determine the business competence and professional suitability of specialists working in various fields of professional activity. The effectiveness of this study, of course, will depend on the course of the experiments.

Project purpose

The purpose of the work is to analyze and study modern approaches to modeling the process of speech communication in the oral and written speech of a specialist, based on knowledge of the fundamental law of conservation of the sum of information and entropy.

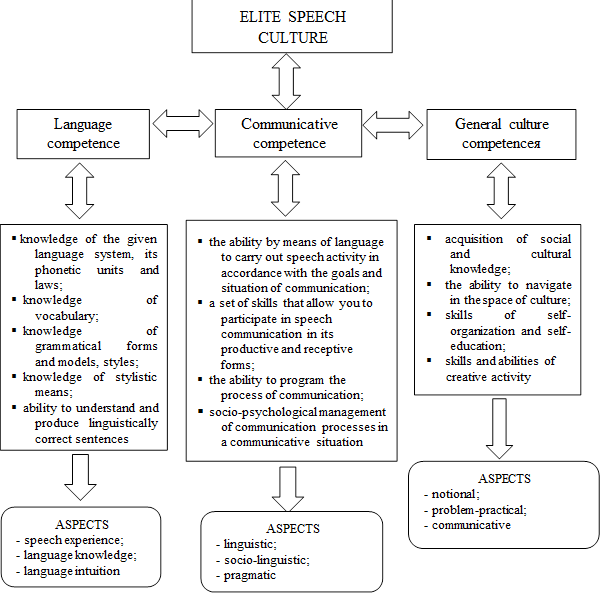

Elite speech culture competence

Results achieved

A linguo-mathematical model has been developed to improve the level of speech culture and improve the professionally oriented language training of specialists.

Applied aspects of the language, speech utterances and stereotypes reflecting the linguistic abilities of a specialist have been analyzed.

Computer programs have been developed that provide speech diagnostics for specialists in various communicative situations, and pilot studies of their effectiveness have been carried out.

A set of programs has been developed to analyze the language training of specialists (the choice of various strategies for speech behavior).

An automated information system has been developed to test the language proficiency of specialists based on the algorithm for the practical implementation of speech.

Model of developing specialists’ speech culture in professional communication

Research team

1 Ospanova Bikesh Revovna – project manager, Cand. Phil, Associate Professor, head of the RL&C Department

ORCID ID 0000-0001-8070-2181

Scopus Author ID 55624338100

2 Galyautdinova Alina Nailovna – principal investigator, MGS, lecturer of the RL&C Department

3 Kazhikenova Saule Sharapatovna – Doctor of Engineering, Professor, head of the HM Department

ORCID ID 0000-0002-6937-1577

Researcher ID P-5627-2017

Scopus Author ID 36106908300

4 Abdin Azat Zhasulanovich – PhD

5 Seilkhanova Ainur Yergaliyevna – doctoral student, sn. lecturer of the “Theories and methods of foreign language training” Department, NJSC Karaganda University n.a. E.A. Buketov

ORCID ID 0000-0002-9087-868X