AP08856371 “Developing a resource-saving technology of repairing long rods of hydraulic cylinders of large-sized special industrial equipment with the possibility of restoring local damage at the site of its operation”. Project manager G.S. Zhetessova

Relevance

At present, for hydraulic cylinders of large-sized special equipment for industrial use, a widespread practice is producing rods with the galvanized chromium coating (GCC), which provides wear resistance, anti-corrosion properties, decreasing the coefficient of friction, and resistance to chemical and thermal effects of the environment. The need to use protective coatings is caused by high loads and severe operating conditions of the equipment. However, when repairing the inevitable local damage to the surface of the rods, it is possible to achieve original characteristics of the product only by completely re-chrome-plating the surface, the cost of which can reach 70% of the cost of the product. The idea of this project is to develop a cheaper alternative technology for the repair of long large-sized rods over the entire surface, as well as with to eliminate local damage based on thermal spraying processes, which will allow carrying out repair work at the site of equipment operation with obtaining a wear-resistant coating that is not inferior in its properties to GCC.

The project purpose

The development of a technology for repairing damage to the chrome-plated surface of long rods of hydraulic cylinders of large-sized special equipment for industrial use based on thermal spraying methods, which will be a cheap, environmentally friendly alternative to the process of re-chrome-plating plating and will provide higher properties of the restored surface compared to other repair technologies used today, and will also give the possibility of carrying out repair work at the site.

Expected and achieved results

- The analysis of the latest scientific developments in the field of coating has been carried out, taking into account the data of the operating conditions of the rods.

- Grades of steels used for manufacturing long large-sized rods have been analyzed.

- Systematization of the data of flake susceptibility, tendency to cracking, etc. has been carried out for rod steels.

- The factors influencing formation of cracks in the studied steels under the given conditions and the development of measures for their prevention have been revealed.

- A method of coating the entire product has been developed.

- A method of local restoration of the damaged layer has been developed.

- An additional data analysis and classification of rod surface damages have been carried out. The nature and dimensions of typical damage to the surface of the rods have been determined.

- A method of preparing the substrate before the local restoration of the surface has been developed, taking into account the nature of the damage and characteristics of the spraying process. The stages of preparing and work execution techniques have been determined.

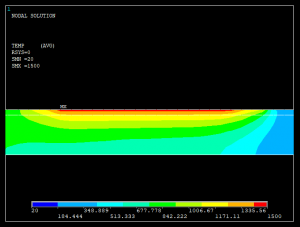

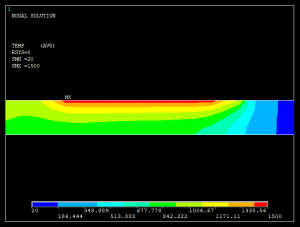

Implementation of the project is based on the use of an integrated research method including a theoretical analysis that is based on the use of static methods of analyzing the properties of steels, which must be taken into account when developing a coating technology. On its basis the experimental verification of the proposed technical and chemical solutions in laboratory conditions has been carried out. All the studies have been carried out according to a single methodology, which allows obtaining reliable results. The project also uses methods of simulation, field and time observation, methods of mathematical statistics and data processing and assessment of their reliability. In the course of solving the tasks in the project, numerical experiments have been carried out using the method of computer modeling (Figures 1, 2), the purpose of which is to assess the thermal effect of the spraying process on the workpiece and to simulate preheating of the surface, taking into account the real dimensions of long large-sized parts.

Temperature distribution (°С) in the wall of the hydraulic cylinder rod (when calculating the hydraulic cylinder 105x90x1000 mm made of 20MnV6 steel, the process duration 50 sec)

in the thermal spraying process:

a) in the model, the hydraulic cylinder rod without thermal spray coating;

b) the rod of the hydraulic cylinder with a formed protective coating based on a nickel alloy with tungsten carbides

The possibility of commercializing the project results is planned by concluding a license agreement with industrial enterprises engaged in the repair, restoration, manufacture, operation of large-sized industrial equipment. It is planned to develop a strategy, a business plan for the further commercialization of the project.

Research team

- Zhetessova Gulnara Santaнevna, project manager, Doctor of Engineering, Professor of the TEME&S department.

ORCID 0000-0001-6504-3405

Researcher ID S-3369-2017

Scopus Author ID 57212376967

- Ibatov Marat Kenessovich, scientific consultant, Doctor of Engineering, Professor of the TE&LSD department.

ORCID iD 0000-0001-5062-7790

ResearcherID N-9320-2017

Scopus Author ID 57189211438

- Olegas Černašėjus, scientific consultant, PhD, Acting Professor of the Engineering of Mechanics and Materials department of Vilnius Technical University named after Gediminas.

Scopus Author ID 22978289800

- Jelena Škamat, scientific consultant, Doctor of Engineering, sn. employee of the Composite Materials Laboratory, Associate Professor of the Mechanics and Engineering of Materials department of Vilnius Technical University named after Gediminas.

ORCID ID 0000-0002-4441-6839

Scopus Author ID 36338084700

Web of Science Researcher ID AAR-4325-2020

- Nikonova Tatyana Yuryevna, responsible officer, Candidate of Technical Sciences, Acting associate professor of the TEME&S department. ORCID 0000-0002-6539-1263

Scopus Author ID 57202087837

- Yurchenko Vassili Viktorovich, PhD, Acting associate professor, Head of the TEME&S department.

ORCID 0000-0002-6543-1632

Scopus Author ID 57213756780

- Zharkevich Olga Mikhailovna, PhD., Acting professor of the TEME&S department.

ORCID 0000-0002-4249-4710

Scopus Author ID 55339344600

- Morozov Petr Yuryevich, M.Sc., hydraulic engineer, Karaganda branch of Ganza-Flex Hydraulic Almaty LLP.

List of publications

– an article in a scientific publication indexed by international databases Web of Science, included in the second quartile and having a Cite Score percentile in the Scopus database of 65 in the scientific direction:

Škamat J, Černašėjus O, Zhetessova G, Nikonova T, Zharkevich O, Višniakov N. Effect of Laser Processing Parameters on Microstructure, Hardness and Tribology of NiCrCoFeCBSi / WC Coatings. Materials. 2021; 14 (20): 6034. https://doi.org/10.3390/ma14206034;

– an article in a Russian journal with a non-zero impact factor recommended by CCES:

Analysizing factors affecting the cracking resistance of steels for rods/ Zhetessova G.S., Nikonova T.Yu., Jelena Škamat, Zhunuspekova D.S., Mateshova A.K.// University Proceedings (CCES), No. 3. P. 61-67;

– participation in international conferences (4 theses):

- Zhetessova G.S., Zhunuspekov D.S. Review of methods of thermal spraying for the restoration of worn parts. Proceedings of the international conference “Innovations in technology and education: collection of articles of the XIII International Scientific and Practical Conference, March 26, 2021, Branch of KuzGTU in Belovo. Belovo: Kuzbass State Technical University named after T.F. Gorbachev, 2021. P. 105-108

- Zhetessova G.S., Zharkevich O.M. Technological parameters of shot blasting effect on surface quality before spraying protective coatings. Collection of proceedings of the international conference “Innovations in technology and education: collection of articles of the XIII International Scientific and Practical Conference, March 26, 2021, Branch of KuzGTU in Belovo. Belovo: Kuzbass State Technical University named after T.F. Gorbachev, 2021. P. 130-133

- Nikonova T.Yu., Zharkevich O.M. Analysizing the use of the technology of surface hardening parts of rotation in the conditions of machine-building enterprises. Proceedings of the international conference “Innovations in technology and education: collection of works of the XIII International Scientific and Practical Conference, March 26, 2021, Branch of KuzGTU in Belovo. Belovo: Kuzbass State Technical University named after T.F. Gorbachev, 2021. – p. 109-112

- Zhetessova G.S., Nikonova T.Yu., Zhunuspekov D.S. Analysizing surface preparation methods before applying a coating by the thermal gas method. Engineering and technology of mechanical engineering: materials of the X Intern. scientific and technical conf. (Omsk, April 26-28, 2021) / Ministry of Education and Science of Russia, Omsk State Tech. Un. Omsk: Publishing house of OmSTU, 2021. P. 118-122

Information for potential consumers

Area of use. The target consumers of the project results can be machine-building enterprises, mechanical parks of large and medium-sized enterprises of the mining industry, repair and service enterprises, manufacturers of hydraulic equipment.

AP08856344. “Developing a complex for remote monitoring of the structural elements of high-voltage transmission lines state in the process of operation based on intelligent noise-immune telemetry systems” Project manager K.S. Sholanov

Relevance

Developing methods of monitoring the volumetric and surface leakage currents of strings of high-voltage insulators during operation that allow developing predictive models of the state of their insulation is an urgent scientific and technical problem. Its solution will make it possible to make informed decisions on the further operation of insulators at an early stage of insulation deterioration with increasing electricity losses.

The project purpose

Reducing losses and accidents during transportation of electricity at high voltage transmission lines with voltage above 110 kV based on interconnected scientific and technical solutions containing the concept, principles of construction and structure of a complex for remote monitoring of the structural elements of high-voltage overhead power transmission lines state during their operation based on intelligent diagnostic noise-immune telemetry systems.

Expected and achieved results

The expected economic effect is to reduce the technical and technological losses of electricity at the HVOPL, to reduce the cost of electricity transportation and increase its reliability.

Methods of monitoring the volumetric and surface leakage currents of high-voltage insulators have been developed and described.

The analysis of the electrical energy converters required for the implementation of the project objectives has been carried out.

The structure of the hardware part of electrical energy converters for autonomous power supplies of monitoring systems has been developed and described.

|

Research team

1. Sholanov Korganbai Sagnayevich, scientific. hands., doctor of technical sciences, professor of the APP department. Scopus Author ID: 56258478400 ORCID 0000-0002-2077-7883 2. Kaverin Vladimir Viktorovich, responsible officer, Candidate of Technical Sciences, Associate professor of the APP department. ORCID 0000-0003-2021-7445 Scopus Author ID 57214729792 3. Voitkevich Sofya Valentinovna, PhD, Acting associate professor of the APP department. ORCID 0000-0003-4267-3468 Scopus Author ID 57191158205 4. Kalinin Alexey Anatolyevich, PhD, Acting head of the ICS department. ORCID 0000-0003-4699-7240 Scopus Author ID 57193550259 5. Em Gennadi Arkadyevich, M.Sc., senior teacher of the APP department. ORCID 0000-0003-2639-0492 6. Ivanov Valeri Anatolyevich, M.Sc., sn. teacher of the APP department. ORCID 0000-0003-2811-7908 Scopus Author ID 57195273869 7. Ashimova Dana Yestayevna, M.Sc. 8. Levin Igor Vitalyevich, Chairman of Progress-Service PC. Scopus Author ID 57195285510 9. Yezhebayeva Sholpan Yesengeldyevna, doctoral student of gr. EE-19D of the APP department. ORCID 0000-0001-5925-1646 10. Saifulin Ruslan Faritovich, doctoral student of gr. EE-18D of the APP department. ORORCID 0000-0003-2610-9525 |

| Laboratory bench for experimental studies of the energy characteristics of various design options for solar panels | |

Experimental stand of the HVOPL diagnostic system |

List of publications

- V. Breido, V.V. Kaverin, S.V. Voitkevich. Complex for diagnostics and monitoring of the state of structural elements of high-voltage power lines. KSTU, 2021. 111 p.

- Breido I.V., Kaverin V.V., Ezhebaeva Sh.E., Shoshymbekova G.T. The issue of creating power supplies for remote monitoring systems of overhead power lines. 2021 University Proceedings, KTU, No. 2 pp. 153-162.

- Patent application No. 21 dated 04/22/20231. I.V. Breido, V.V. Kaverin, S.V. Voitkevich. Method of automatic remote telemetry in the power industry.

Information for potential users

Area of use. Machine-building enterprises, mechanical parks of large and medium-sized enterprises of the mining industry, repair and service enterprises, manufacturers of hydraulic equipment.

AP08855477 “Developing and implementing the technology of producing Nihard-class cast irons with improved operational properties for parts of mining and metallurgical equipment” Project manager A.Z. Issagulov A.Z.

Relevance

A number of parts for mining and metallurgical equipment are made of Nihard cast irons (grates, fittings, plates, pump parts, etc.). Despite significant advantages of using these cast irons, they also have their own disadvantages: relatively poor casting properties (low fluidity, high shrinkage), besides, cutting when manufacturing parts of castings is difficult. In this project, it is planned to ensure the required operational and technological properties of Nihard grade cast irons in relation to specific parts of equipment of mining and processing plants by selecting the state of the metal base, applying corrected alloying and modification, using improved modes of crystallization and heat treatment. The issue of making thin-walled and shaped castings will also be resolved.

The project purpose

Developing and implementing the technology of producing parts for mining and metallurgical equipment using Nihard cast iron with an optimal set of properties depending on the operating conditions of the parts, which will increase the service life by 1.5-2 times.

Expected and achieved results

Based on the information analysis and taking into account the development of foundry production in the Republic of Kazakhstan, the optimal casting method of obtaining products of Nihard cast irons was determined, tendencies for improving the structure and properties of Nihard cast irons were determined, taking into account the raw materials base of the Republic of Kazakhstan.

Based on the results of primary laboratory studies, the optimal composition of the cold-resistant mixture for cast irons of the Nihard class was determined (refractory filler quartz sand 89% (in the proportion 1K0315 65%+1K02 35%), clay 2%; resin 7 – 8%, hardener consumption 1%, glycerin 0.03%).

|

|

|

а |

б |

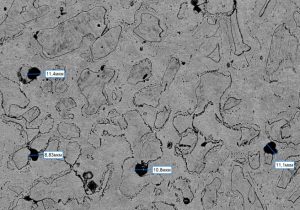

a – Nihard 2 (martensitic-bainitic matrix, carbides); b – alloy 3 (non-etched structure, nodular graphite)

Figure – Structure of alloys X 1000

A new alloy composition has been developed based on Nihard cast iron including carbon, silicon, manganese, nickel, molybdenum, chromium, copper, cerium, iron and titanium carbide with the following ratio of components, wt%: С 2.6-3, 0; Si 1.5-2.5; Mn 0.6; Ni 4.0-5.0; Cr 3.0-5.0; Mo 0.5; Ce 0.1-0.15; TiC 0.5-1.0; Cu 0.2; S≤0.05; P ≤ 0.09; Fe the rest. The main difference of this alloy in comparison with analogs is a change in the Cr:Si ratio, which leads to the appearance of a certain amount of nodular graphite in the structure after modification. The structure of the developed alloy is represented by a ledeburite matrix, carbides and nodular graphite in the amount of 4 – 6%, which leads to an increase in the resistance to abrasive wear. The introduction of titanium carbide helps to simplify the shape of the primary graphite and to intensify the process of subsequent spheroidization. The proposed alloy has increased resistance to abrasive wear by 20 – 25% higher than Nihard 2. An application for a patent of the Republic of Kazakhstan has been filed for this composition.

The proposed composition of the cold-hardening mixture including, wt%: 3-5 phosphoric acid; 2-10 highly dispersed filler (dust from gas cleaning in the production of ferrosilicon); 4-6.6 water and quartz sand. The proposed mixture is characterized by high strength and vitality. The molds obtained from the proposed mixture make it possible to obtain castings from chromium-nickel cast irons of high precision and surface cleanliness. A patent of the Republic of Kazakhstan for a utility model was obtained for this composition.

A mode of processing (modification) is proposed, which consists in introducing a complex modifier based on ferrosilicon with magnesium and a composition of rare earth metals with a dispersion of 0.5-2 mm in an amount of 0.5-1%. The treatment with this modifier in the specified amount promotes the formation of nodular graphite with an average inclusion diameter of 35-40 microns, which provides an increase in wear resistance by 20 – 25% compared to Nihard 2.

|

Research team

1 Issagulov Aristotle Zeynullinovich, project manager, Doctor of Engineering, Professor of the NTM department. ORCID 0000-0003-2174-9072 Researcher ID C-7415-2016 Scopus Author ID 57211295299 2 Kulikov Vitali Yurievich, responsible officer, Candidate of Technical Sciences, professor, acting head department Ntm ORCID 0000-0001-6191-8569 Researcher ID N-5596-2017 Scopus Author ID 56168395900 3 Ibatov Marat Kenessovich, scientific. consultant, Doctor of Engineering, Professor of the TE&LSD department. ORCID iD 0000-0001-5062-7790 ResearcherID N-9320-2017 Scopus Author ID 57189211438 4 Kvon Svetlana Sergeyevna, Candidate of Technical Sciences, Associate Professor of the NTM department. ORCID 0000-0002-5439-4426 Researcher ID N-5602-2017 Scopus Author ID 5706189240 |

5 Shcherbakova Yelena Petrovna, PhD, an. Teacherof the NTM department.

ORCID 0000-0001-6678-6673

Researcher ID N-5639-2017

Scopus Author ID 55543103900

6 Issagulova Diana Aristotelevna, PhD, Acting ass. professor of the NTM department.

7 Dostayeva Ardak Mukhamedievna, PhD, sn. teacher of the NTM department.

ORCID 0000-0002-1982-2368

Researcher ID AAB-9478-2020

Scopus Author ID 57160297400

8 Arinova Saniya Kaskatayevna, PhD, teacher of the NTM department.

Scopus Author ID 57192206332

9 Dospayev Murat Mantenovich, Doctor of Engineering, Chief Researcher of the Chemical-Metallurgical Institute named after V.I. Zh.Abishev, RSE “National Center of Integrated Processing of Mineral Raw Materials of the Republic of Kazakhstan”

Scopus Author ID 57204316546

List of publications

1 Kosnikov G.A., Matveyev I.A., Kovalev P.V., Kulikov V.Yu., Kvon St.S. World tendencies in the field of improving the properties of alloyed cast irons // Proceedings of the University, Karaganda: Publishing house of KTU. – 2021. – No. 1. – P. 15-19.

2 Issagulov A.Z., Kulikov V.Yu., Kvon Sv.S., Ibatov M.K., Arinova S.K., Dostayeva A.M. Comparative analysis of graphite inclusuons in chrome cast iron structure // Metalurgija, Croatia: Croatian Metallurgical Society. – 2021. – No. 3-4 (60). – P. 285-288 (IF Scopus 0.388, Scopus percentile 57).

3 Kulikov V.Yu., Kvon Sv.S., Dostayeva A.M., Shcherbakova Ye.P., Arinova S.K., Alina A.A. Highly dispersed filler in the composition of cold-hardening mixtures effect on its technological properties // Foundry of Russia, Moscow: All-Russian public organization “Russian Association of Foundry”. – 2021. – No. 3. – P. 15-17.

4 Osipenko L.A., Issagulov A.Z., Repyakh S.I., Kulikov V.Yu., Kvon Sv.S., Shcherbakova Ye.P. Cold-hardening mixture for molds and cores // Foundry, Moscow: Publishing house “Foundry”. – 2021. – No. 6. – S. 18-21.

5 Issagulov A.Z., Ibatov M.K., Kovalev P.V., Shcherbakova Ye.P., Dostaeyva A.M., Arinova S.K. Publishing house of Kartu. – 2021. – No. 2. – P. 47-51.

6 Kovalev P.V., Kulikov V.Yu., Alina A.A. Organic binder compositions of cold curing under the action of liquid catalysts and hardeners // Proceedings of the International Scientific and Practical Conference “Integration of Science, Education and Production – the Basis for the Implementation of the Plan of the Nation” (Saginovsky Readings No. 13) (June 17-18, 2021) – Karaganda, 2021. P. 1310-1312.

7 Issagulov A.Z., Kvon Sv.S., Ibatov M.K., Kulikov V.Yu., Shcherbakova Ye.P. Developing the technology of producing Nihard cast irons with enhanced properties: Monograph. Kazakhstan. Ed. IP KTU, 2021.103 p. ISBN 978-601-355-004-6.

8 Issagulov A.Z., Kulikov V.Yu., Kvon Sv.S., Ibatov M.K., Shcherbakova Ye.P. Studying properties of chrome cast irons modified with titanium carbide // Metalurgija, Croatia: Croatian Metallurgical Society. – 2021. – No. 3-4 (60). – P. 299-302 (IF Scopus 0.388, Scopus percentile 57).

9 Issagulov A.Z., Kulikov V.Yu., Kvon Sv.S., Shcherbakova Ye.P. Improving the mechanical properties of Nihard class cast irons // Foundry, Moscow: Foundry Production Publishing House. – 2021. – No. 10. – P. 9-11.

10 Issagulov A.Z., Ibatov M.K., Kulikov V.Yu., et al. Mixture for manufacturing casting molds and cores // Patent of the Republic of Kazakhstan for utility model No. 6098, published on May 28, 2021.

Patent pending

1 Ibatov M.K., Issagulov A.Z., Kvon Sv.S., et al. The composition of wear-resistant cast iron // Application for the patent of the Republic of Kazakhstan No. 2021/0124.1 dated 23/02/2021

Information for potential consumers

The obtained scientific results can be used in the development of new industries and areas of metallurgical and foundry industries, new technological processes of smelting and modes of out-of-furnace and heat treatment of alloys, partially extended to other grades of alloys with special properties.

AP08856688 “Developing methods of isolating natural triterpenoids from plants and their chemical transformation in order to search for new biologically active substances”. Project manager A.T. Takibayeva

Relevance

Natural triterpenoids and their derivatives attract attention of researchers around the world looking for new bioactive agents due to their widespread use and synthetic potential. Modification of molecules of triterpenoids and their derivatives with subsequent bioscreening of the obtained compounds is relevant for the development of new highly effective drugs with a wide spectrum of pharmacological action.

The project purpose

Studying and developing effective methods of isolating natural triterpenoids from domestic plants for subsequent synthesis of new biologically active derivatives on their basis.

Expected and achieved results

Derivatives of betulin have been obtained by reacting it with phenylferrocenyl alcohol, glyoxalic acid and tetramethylglycoluril, dimethylphosphate. Synthesizing and studying the structure-bioactivity relationship of the obtained compounds have been carried out.

Methods of obtaining and optimal conditions for synthesizing triterpenoid derivatives under conditions of classical synthesis, microwave and ultrasonic activation have been developed; pharmacologically active derivatives of triterpenoids have been obtained by heterocyclization of hydroxyl-substituted betulin. Physicochemical and spectral characteristics, the structure-bioactivity relationship of the synthesized substances have been studied.

The bioscreening of the activity of new functionally substituted triterpenoids and their derivatives for antioxidant, antimicrobial, anti-inflammatory and other types of biological activity has been carried out.

|

Research team

1. Takibayeva Altynarai Temirbekovna, project manager, Candidate of Chemical Science, head of the C&CT department. ORCID iD 0000-0003-0536-0817 Scopus Author ID 12808279300 2. Kassenov Rymkhan Zeinollayevich, responsible officer, Candidate of Chemical Science, Ass. professor of the Organic chemistry and polymers department of NAO Karaganda University named after E.A. Buketov. ORCID iD 0000-0002-9832-5115 Scopus Author ID 56616120800 3. Ibrayev Marat Kirimbayevich, Doctor of Chemical Science, Professor of the C&CT department. ORCID iD 0000-0003-0798-5562 Scopus Author ID 6508179234 Researcher ID V-9320-2018 4. Issabayeva Meruert Berdeshevna, Candidate of Chemical Science, Associate professor of the C&CT department. ORCID iD 0000-0002-7053-8610 Scopus Author ID 14219273700 Scopus Author ID 14831459000 5. Akhmetova Saule Baltabayevna, Candidate of Medical Science, Professor-researcher, head of the Clinical Immunology, Allergology and Microbiology department of NAO Medical University of Karaganda Scopus Author ID 25030129100 6. Zhumadilov Sayat Sagatovich, doctoral student of NAO Karaganda University named after E.A. Buketov ORCID iD 0000-0002-4046-311X 7. Demets Olga Vladimirovna, doctoral student of the Research Institute of Tomsk State University, sn. laboratory assistant of the C&CT department. ORCID iD 0000-0002-9440-4668 |

| Alieva M.R. conducts recrystallization of betulin at Research Institute “Tomsk State University” | |

|

|

| Demets O.V. conducts synthesis on the interaction of betulin with phenylferrocenyl alcohol in the presence of trifluoroacetic acid at the Research Institute “Tomsk State University” |

- Aliyeva Madina Ramankulovna, M.Sc., sn. teacher of the C&CT department.

ORCID iD 0000-0003-0819-2484

- Lyapunova Maria Vyacheslavovna, chemist of the Organic synthesis laboratory, RI at Tomsk State University

- Ospanov Bekarys, master student of gr. HTOVM-21-1 of the C&CT department.

List of publications

- Takibayeva A.T., Kasenov R.Z., Demets O.V., Zhumadilov S.S., Bakibayev A.A. Derive betulin from Kyrgyz birch bark (Betula kirghisorum) hrough alkaline hydrolysis and microwave radiation methods. Reports of the National Academy of Sciences of the Republic of Kazakhstan, Vol. 4, Number 338(2021), P. 87-92.

- Takibayeva A.T., Kasenov R.Z., Demets O.V., Bakibayev A.A. Isolation of betulin from birch bark (betula kirghisorum) by the ultrasonic activation method. Reports of the National Academy of Sciences of the Republic of Kazakhstan, Vol. 5, Number 339 (2021), P. 182-188.

- Takibayeva A.T., Demets O.V., Kassenov R.Z. Isolation of betulin from birch bark of Kyrgyz birch (Betula Kirghisorum) by microwave activation and study of its quantitative yield // Tr. International scientific-practical online conf. “Integration of science, education and roduction as the basis for implementing the Plan of the Nation” (Saginov’s readings No. 13) dedicated to the 30th anniversary of the Independence of the Republic of Kazakhstan, June 17-18, 2021. – Karaganda: KTU Publishing House, 2021, pp. 1901-1903.

- Lyapunova M.V., Mishina A.E., Malkov V.S., Bakibayev A.A. Transformation of betulin and its esters under conditions of mechanochemical activation // Pr. International scientific-practical online conf. “Integration of science, education and production – the basis for the implementation of the Plan of the Nation” (Saginov’s readings No. 13) dedicated to the 30th anniversary of the Independence of the Republic of Kazakhstan, June 17-18, 2021. – Karaganda: KTU Publishing house, 2021. – P. 1865-1866;

- Shvartskop I.S., Lyapunova M.V., Malkov V.S., Bakibayev A.A. Synthesizing some oximes based on ferrocene ketones and their reduction // Tr. International. scientific-practical online conf. “Integration of science, education and production – the basis for the implementation of the Plan of the Nation” (Saginov’s readings No. 13) dedicated to the 30th anniversary of the Independence of the Republic of Kazakhstan, June 17-18, 2021. – Karaganda: KTU Publishing house, 2021, pp. 1924-1925.

- A.A. Bakibayev. M.V. Lyapunova, A.T. Takibayeva, E.A. Mamayeva, O.V. Demets, M.R. Aliyeva, V.S. Malkov. Methods of preparation, purification and identification of betulin and related compounds. Monograph. – Karaganda: SANAT-POLYGRAPHIYA, 2021, 179 p.

- Patent of the Republic of Kazakhstan for a useful model No. 6483 dated 08/10/2021. Takibayeva A.T., Kassenov R.Z., Ibrayev M.K., Demets O.V., Aliyeva M.R. Method of separating betulin from birch bark of Betula Kirghisorum.

Information for potential consumers

Area of use. Chemistry, medicine and pharmaceutical industry.

Effective methods of isolation have been developed and potentially biologically active derivatives based on betulin have been obtained. Betulin isolated from Betula kirghisorum, expands the understanding of the inexhaustible possibilities of chemical transformation of triterpenoids and can be used both for large-scale production of new derivatives and chemical synthesis based on it.

AP08856918 “Developing a linguo-mathematical aggregated model of specialists’ speech diagnostics based on methods of the theory of the language structure self-organization”. Project manager B.R. Ospanova B.R.

Relevance

The project relevance consists in the possibility of using the linguo-mathematical aggregated model of speech diagnostics to determine the business competence and professional suitability of specialists working in various fields of professional activity.

The project purpose

On the basis of an interdisciplinary approach, taking into account the connection between modern linguistics and computer technologies, to substantiate the need for developing a new type model that can characterize speech activity of a specialist and contribute to the formation of an elite linguistic personality with high cultural competence.

Expected and achieved results

A hierarchical scheme of verbal and cognitive processes based on the linguistic activity of a specialist has been developed.

The applied aspects of competence possession have been developed reflecting the linguistic abilities of a specialist with the use of modern information technologies.

Experimental studies have been carried out to identify communicative defects in oral spontaneous speech among bachelor, master and doctoral students of Karaganda Technical University and the Peoples’ Friendship University of Russia (Moscow).

A linguo-mathematical model has been developed to identify communicative defects in oral speech based on the Shannon law of conservation of the sum of information and entropy. For the first time, on the basis of the fundamental law of conservation of the sum of information and entropy, individual emotional and motivational processes of human speech activity will be identified on the basis of computer technologies.

The developed automated information system will allow checking the language readiness of specialists to identify the indicator of speech diagnostics in various communicative situations.

|

Research team

1. Ospanova Bikesh Revovna, project manager, Canf. Phil., Associate professor, Head of the RL&C department. ORCID iD 0000-0001-8070-2181 Scopus Author ID 55624338100 2. Abdin Azat Zhasulanovich, responsible officer, M.Sc., engineer of the RL&C department. ORCID iD 0000-0003-4016-0204 3. Kazhikenova Saule Sharapatovna, Doctor of Engineering, Professor, Head of the HM department. ORCID iD 0000-0002-6937-1577 Researcher ID P-5627-2017 Scopus Author ID 36106908300 4. Seilkhanova Ainur Yergaliyevna, doctoral student, sn. lecturer of the Theory and Methods of Foreign Language Training department of NAO Karaganda University named after E.A. Buketov 5. Akynzhanova Alma Akynzhanovna, M.Sc. ORCID iD 0000-0002-4895-0561 |

List of publications

- Ospanova Bikesh Revovna, Seilkhanova Ainur Yergaliyevna, Abdin Azat Zhasulanovich. Using the fundamental law of conservation of the sum of information and entropy on the basis of modeling the process of speech communication in oral and written speech. CIP No. 14707 dated January 27, 2021.

- Ospanova B.R., Seilkhanova A.E., Akynzhanova A.A., Abdin A.Zh. Practical models of the mechanism of the functioning of linguistic units in speech. CIP No. 15848 dated March 11, 2021.

- An article published in the Scopus database journal: Predictive modeling of burnout among kazakhstani english teacher candidates, SCHOLARLY JOURNAL, DOI: 10.17853 / 1994-5639 ISSN 1994-5639 (Print), 2310-5828 (on-line), Vol. 23, No. 2. 2021.

- Ospanova B.R., Abdin A.Zh., Seilkhanova A.Ye., Akynzhanova A.A. Building a model of a syntactic analysis and speech recognition system based on statistical sets of word parameters (the work is funded by the Science Committee of the Ministry of Education and Science of the Republic of Kazakhstan (IRN No. AP08856918). CIP No. 16890 dated April 22, 2021

- Ospanova B.R., Seilkhanova A.ye., Akynzhanova A.A., Timokhina T.V. Using modern approaches to modeling the process of speech communication in the process of professional activity. Pr. of the International scientific and practical conference “Scientific practice: modern and classical research methods”. Boston, USA.

- Ospanova B.R., Seilkhanova A.Ye., Akynzhanova A.A., Timokhina T.V. Features of the study of speech diagnostics based on the methods of the theory of language self-organization. Pr. International scientific Internet conference “Trends and prospects for the development of science and education in the context of globalization” Ukraine, Pereyaslav, University of Grigory Skovoroda. (International Scientific and Practical Conference).

- Ospanova B.R., Seilkhanova A.Ye., Abdin A.Zh. Algorithmic models of methods for studying the processes of speech activity with the use of computer technologies. CIP No. 20198 dated September 9, 2021.

- Ospanova B.R., Kazhikenova S.Sh., Seilkhanova A.Ye. Linguo-mathematical models based on the application of the fundamental law of conservation of the sum of information and entropy. CIP No. 20288 dated September 16, 2021.

- An integrative approach in creating a model of a specialist’s speech competence/ B.R. Ospanova, N.A. Kassenova, A.Ye. Seilkhanova, A. Zh. Abdin, Bulletin of KazNU. Philological series, [S.l.], V. 183, No. 3, Sep. 2021. ISSN 2618-0782 (RK MES CCES).

- Oral speech of future specialists in the assessment of teachers/ B.R. Ospanova, A.Ye. Seilkhanova, A.A. Akinzhanova, T.V. Timokhina// Bulletin of Karaganda University, Series “Pedagogy”. No. 3 (103)/2021 (RK MES CCES).

Information for potential consumers

The theoretical provisions and practical results can be used in training courses on the language theory, special courses in mathematical linguistics, the information theory, and the theory of speech communication.

The theoretical and further studies and practical results obtained within the framework of the project, as well as the experience accumulated by the project participants, allow moving onto a new stage of research: the development of private models that help to reveal the mechanism of the linguistic units functioning in speech.

The results of the project will make it possible to apply qualitative and quantitative assessments of the perception of the level of speech competence.

AP08956387 “Developing a prototype of a universal device based on a lathe for implementation of milling technology”. Project manager M.M. Mussayev

Relevance

The results of the studies carried out show that in the conditions of machine-building enterprises in Kazakhstan, more than half of the parts undergoing machining belong to the parts of bodies of revolution or have arcuate outer surfaces that are machined by turning. It has also been found that during turning there are problems of ensuring the accuracy and quality of turning associated with chip crushing, the occurrence of an impact load on the cutter. These disadvantages also lead to reduced productivity and tool life.

Conventional cutting of high-strength steels is characterized by extremely low plastic deformation during chip formation. There is usually no build-up when machining these materials. For these reasons, tool wear is very intense and occurs primarily along the flank surface. To solve this problem, a technology is proposed for turning parts of bodies of revolution by the method of thermo-friction milling.

The project purpose

Improving the productivity, accuracy and quality of machining parts of bodies of revolution.

Expected and achieved results

Working drawings of parts (an intermediate shaft, half-couplings, a cover, a support bracket, a plate, a rubber elastic element) and assembly drawing of the milling device were developed.

Technological processes of machining parts and the technological scheme for assembling a device for milling were developed.

On the basis of the design documentation developed at the previous stage of the project and procured through grant financing of consumables and equipment, parts and assemblies of a prototype of a special device were manufactured, such as: an intermediate shaft, a base plate, a support bracket, couplings, elastic elements. For further testing the device and implementing the technology of thermo-friction milling, tools and tooling were designed and manufactured, in particular, a friction cutter.

A prototype of a special device for a lathe was assembled in the KTU laboratory.

|

Research team

1 Mussayev Medgat Muratovich, project manager, PhD, Acting associate professor of the TEME&S department. ORCID iD 0000-0001-9875-8159 Scopus Author ID 57194834421 Scopus Author ID 57220743851 2 Rakishev Asset Karigulovich, reponsible officer. executor, PhD, head of the Commercialization Office of KTU Scopus Author ID 57194831172 3 Ainabekova Saule Serikbayevna, M.Sc., sn. teacher of the Processing of metals by pressure department of Karaganda Industrial University. ORCID iD 0000-0002-7033-2225 Scopus Author ID 57201701967 4 Karsakova Nurgul Zholayevna, doctoral student of gr. MSD-20 of the TEME&S department. Scopus Author ID 57208443649 5 Sauletov Suttizhan Rustemuly, master student of gr. MSM 19-1 of the TEME&S department. |

|

|

| To study the thermal processes occurring in the process of milling, a model of parts and assemblies of the device has been prepared |

List of publications

1 Mussayev M.M., Sherov K.T., Rakishev A.K., Karsakova N.Zh., Ainabekova S.S., Okimbayeva A.E. Modernization of designing the device for milling // Natural and technical sciences. – No. 3 (154) – 2021. – P. 133-136.

2 Mussayev M.M., Sherov K.T., Rakishev A.K., Karsakova N.Zh. A universal device based on a lathe for implementation of milling technology // Proceedings of the Int. scientific-practical online conf. “Modern engineering innovations and technologies”. – Kokshetau, 2021. – Vol. 1. – P. 29-27.

3 Mussayev M.M., Sherov K.T., Karsakova N.Zh. Innovations in technology and education // Proc. of XIII int. scientific-practical conf. “Innovation in technology and education.” – Belovo: KuzSTU n.a. T.F. Gorbachev, 2021. – P. 127-129.

4 Mussayev M.M., Karsakova N.Zh. Design of a special device for the implementation of milling technology // Proceedings of Int. scientific-practical online conf. “Integration of science, education and production is the basis for the implementation of the Plan of the Nation” (Saginovskie readings No. 13). – Karaganda: KTU Publishing house 2021. – P. 1462-1463.

5 Mussayev M.M., Sherov K.T., Rakishev A.K., Karsakova N.Zh. Designing an elastic coupling of a universal device based on a lathe for implementation of milling technology // University Proceedings. – Karaganda: KTU Publishing house, 2021. – No. 3 (84). – P. 42-47.

6 M.M. Mussayev, K.T. Sherov, T.M. Buzauova, A.K. Rakishev, N.Z. Karsakova, N.B. Abisheva, S.S. Ainabekova. Studying the stress-strain state of a more loaded node of a special device for turn-milling // Metalurgija, 61 (2022) 1, 247-249.

7 Mussayev M.M., Karsakova N.Zh., Zhakypbekov Zh.A. Studying rigidity of the main components of a universal device // Proc. of LI-LII Int. scientific-practical conf. “Engineering Sciences: Problems and Solutions”. – M.: Internauka, 2021. – No. 8-9 (47). – P. 52-57.

8 Mussayev M.M., Karsakova N.Zh. Designing an elastic coupling of the milling machine // M.: Internauka, 2021. – No. 35 (211). Part 2. – P. 21-24.

9 RK patent No. 6488 RK for a utility model. Universal device for combined processing / М.М. Mussayev, K.T. Sherov, A.K. Rakishev, N. Zh. Karsakova, S.S. Ainabekova, et al; publ. 10/08/2021.

10 Mussayev M.M., Sherov K.T., Karsakova N.Zh. Thermofriction milling machine: Monograph. – Karaganda: Sanat-Polygraphy, 2021. – 120 p.

Information for potential consumers

Area of use. Mechanical engineering industry.