About scientific schools of the NTM Department

The Department of Nanotechnology and Metallurgy conducts research in the following areas: surface hardening of steel products by pre-microalloying and subsequent laser treatment; processes of pulsed and dynamic sealing of molds and the choice of parameters of molding machines; certification of quality control systems for castings; research of the structure, properties of metal and the development of new grades of alloys and their technology industrial production; development of devices and devices for determining the technological and rheological properties of molding mixtures; research and implementation of new technological processes for obtaining castings by special types of casting.

The scientific school functions most effectively under the guidance of Doctor of Technical Sciences, Professor A.Z. Isagulov.

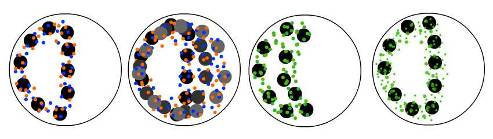

The department has created a unified mathematical model of pulse compaction of shapes, implemented on a PC. The processes of mold manufacturing, the theory of compaction (deformation) of the molding mixture under dynamic loads based on rheological methods and visco-plastic compressible media have received worldwide recognition. The method of calculating the basic design and technological parameters of molding machines and automatic machines of this principle of operation is used in the operation of automatic molding lines of Georg Fisher (Switzerland) and BMD (Germany). Automatic pulse forming machines have been developed for the first time. 85 copyright certificates and patents have been obtained for designs and methods of forms.

The result of the school’s activities was an increase in the uniformity of density and an increase in the strength of the shell mold from both clad and unpainted mixtures. An important area of scientific research is the development of models of dispersed media under simultaneous static and thermal loading. For the first time, scientists of the department proposed the use of non-stationary loading in the processes of forming sand-resin mixtures, a computer program has been developed that simulates processes that allow determining the optimal technological parameters of sand-resin molds, and is used in the educational process and in engineering calculations; and the developed technology for the manufacture of sand-resin casting molds allows you to obtain castings with high dimensional accuracy and the cleanliness of the surface. The technology is used at KMZ LLP. Parkhomenko” (Karaganda).

The use of static loads for forming the shell simultaneously with heating the sand-resin mixture helps to equalize the properties according to its volume. At the same time, the mechanical properties of the resulting shell forms are also increased, which makes it possible to reduce the use of an expensive binder.

A number of works are devoted to the manufacture of sand-resin media (molds, rods, briquettes) with increased hardness and strength in domestic and foreign science. Research is being conducted to improve the equipment, technology and formulations used in the manufacture of such media.

The use of technology for manufacturing sand-resin casting molds using non-stationary pressure has:

- social effect – reducing the cost of products by reducing the cost of castings;

- economic effect – reduction of the cost of casting by 30 % compared to casting in sand-clay molds;

- ecological effect – reduction of dust emission due to the use of sand-resin molds;

- import substitution effect – providing the domestic market of the Republic of Kazakhstan with high – quality cast blanks.

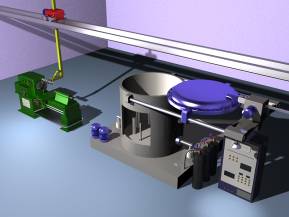

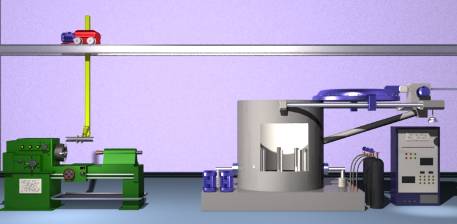

The molding machine of the brand 51713, retrofitted with a press plate in the hopper:

a – from the side of the hopper and the model plate; b – from the side of the control panel

Aristotle Zeynullinovich Isagulov received the award of the competition “Best researcher – 2021”.

The scientists of the department work closely with such reputable organizations in this field as the RosAtom State Atomic Energy Corporation (Russia), the CIRIMAT laboratories of the Paul Sabatier University – the French Aeronautics Center, the Ecole de Mines of the University of Lorraine (France), the Berlin Technical University (Germany), and the leading technical and technological universities of Russia – NUST “MISiS, Peter the Great SPbPU, IRNIT, as well as ArcelorMittal Temirtau JSC, Kazakhmys Corporation LLP and other industrial companies of the mining and metallurgical complex of Kazakhstan.

About the laboratories of the NTM Department

The Center for Heat-resistant Materials was established on the basis of the KORMS Engineering Laboratory, the International Center for Materials Science of the Karaganda State Technical University and with the support of the Ministry of Education and Science of the Republic of Kazakhstan (Program-targeted financing Agreement No. 569 dated April 7, 2015).

The research of the Center is the development of Sintering-casting technology. As is known, cermets obtained by conventional methods of powder metallurgy have high hardness and wear resistance, but at the same time they differ in sufficiently low impact strength, ductility and high brittleness. This makes it difficult to process them and limits their use, both at room temperatures and at elevated temperatures.

A number of studies have shown that the use of the impregnation method in the production of cermets can significantly improve their operational properties. When using this method, the metal phase, which serves as a binder, is added not in powdered form, but in the form of a liquid introduced by impregnation. As a result of this process, the skeleton of the workpiece, prepared by pressing the powder at low pressure, is sintered, forming a sufficiently dense mass, while the pores are filled with a metal bundle providing the necessary properties. The impregnation method makes it possible to obtain low-porous products of perfectly regular shape with minimal deviations from the specified dimensions; in many ways, these products resemble precision casting.

For a series of works on the topic: “Development of heat–resistant alloys and new generation technologies for the production and processing of parts based on them” (scientific supervisor – Doctor of Technical Sciences, Professor Isagulov A.Z., authors – Doctor of Technical Sciences, Professor Ibatov M.K., Doctor of Technical Sciences, Professor Suleimenov T.S., Doctor of Technical Sciences, Professor Zhetesova G.S., K.In 2020, a group of scientists was awarded the al-Farabi State Prize of the Republic of Kazakhstan in the field of science and technology.

Heat-resistant alloy, regardless of its composition, has a higher price than steel. Therefore, parts made of heat-resistant alloys must be as accurate as possible in order to avoid losses of expensive metal during subsequent processing. The scientists of the department have successfully solved this problem. They have improved the casting technology for gasified models, which allows casting high-quality parts from heat-resistant alloys with minimal metal losses.

The implementation of improved casting technology and the use of a new heat-resistant alloy made it possible to obtain a number of necessary parts of metallurgical equipment, such as furnace rollers, trunnions, tips, which have a service life of 30-40% higher than previous analogues. Scientists have obtained not only Kazakhstani, but also Eurasian patents for the composition of the new alloy and the technology of manufacturing parts from this alloy, which confirms the importance and novelty of these developments.

The authors have proposed, at the level of numerous inventions, compositions of new heat-resistant alloys comparable in properties to “Nimonics”, but lower in cost by 20-25%.

Parts made from a new alloy and according to the developed technology, 2019-2021.

The advantage of the work is not only its practical significance, but also the fundamental nature of the research performed. Thus, for the first time in the world, a methodology has been developed for assessing the conditions for the formation of new reinforcing “intermetallic” phases in heat-resistant alloys, mechanisms for hardening dispersed mixtures during shaping have been established, activation conditions for “galloisite” nanotubes from natural minerals have been determined, and many others.

The grant for the establishment of the International Center for Materials Science (ICM) within the framework of the Technology Commercialization project dated June 21, 2013, was a subproject in order to promote international standards in research, develop and deepen cooperation with the international scientific society and industry.

The objectives of the creation of the International Center for Materials Science (ICM):

– Creation and provision of access for scientific research based on the use of a website and an information portal in the field of materials science by domestic and foreign scientists.

– Providing access to information from the central hub for information exchange and resource sharing for the scientific research community of Kazakhstan.

– Ensuring the conduct of research and development work (R&D) by subjects of scientific and scientific and technical activities.

– Coordination of the activities of national laboratories, collective use laboratories, research centers in a single virtualization space with laboratories and centers Abroad.

The activities of the International Center for Materials Science are considered as ensuring the conduct of research and development work by subjects of scientific and scientific-technical activities in the field of materials science and the mining sector, and also promotes cooperation between senior and junior researchers and the involvement of undergraduates in research activities.

Research projects of the Department “Technological Equipment, Mechanical Engineering and Standardization” (TOMiS) :

A number of grant research projects are being implemented at the Department of Technological Equipment, Mechanical Engineering and Standardization

| Name of the topic | Project Manager |

| Design and creation of prototypes of automated production control systems, remote monitoring and diagnostics of the microclimate in polymer agricultural sleeves for grain storage (2021-2023) | Никонова Т.Ю. |

| Development of resource-saving technology for repairing long rods of hydraulic cylinders of large-sized special equipment for industrial purposes with the possibility of restoring local damage at the place of its operation (2021-2023) | Жетесова Г.С. |

| Development of compositions of sand-polymer composite materials and technological support for their processing into machine-building products (2023-2025) | Никонова Т.Ю. |

| Increasing wear resistance and improving the design of the tire punching machine tool (2023-2025) | Мусаев М.М. |

| Creation of a universal prototype gear pump for hydraulic systems capable of pumping viscous liquids of various natures (2023-2025) | Жаркевич О.М. |

| Development of software for technological preparation of production based on the formalized design methodology (2022-2024) | Савельева Н.А. |

The results of research are not only multibillion–dollar economic effects, but also 16 monographs and more than 100 textbooks and over 1000 articles in scientific journals. The scientific research of the department is developing in the following areas: threading, electrocontact processing, intermittent grinding, quality management in mechanical engineering, the creation of MRC structures from half-concrete, computer-aided design systems in mechanical engineering. Senior students, undergraduates and doctoral students take part in all these studies. A number of students and their supervisors were awarded certificates and diplomas from the Ministry of Education and Science of the Republic of Kazakhstan.

As a result of research, the rights to scientific products are registered annually:

– Nurzhanova O.A., Zhukova A.V., Zharkevich O.M. Calculator of the hardness of the deposited layer;

-Teliman I.V., Raiskaya E.I. Simulator simulator of an electric excavator;

– Zhunuspekov D.S., Nikonova T.Yu., Dandybaev E.S., Savchenko N.K. Piece time calculator.

Monographs

1) Musaev M.M., Sherov K.T., Karsakova N.J. Thermofriction frezalap jonuga arnalgan kurylgy. Kazakhstan, Map named after Abylkas Saginov, 2023. – 120 b.

2) Nikonova T.Yu., Zharkevich O.M., Dandybayev E.S., Baimuldin M.M., Kotov E.S. Creation of an automated system for control of the thickness of the polymer film. – Karaganda: print house of “Tengi ltd”, 2022. – 94 p.

3) Zhetessova G.S., Skamat Je., Cernasejus O., Nikonova T. Yu., Zharkevich O.M., Yurchanko V.V., Khrustaleva I.N., Zhunuspekov D.S. Development of a tehnology for the repair and resroration of long rods using thermal spraying methods. – St.Peterburg: Polytech-Press, 2022. – 100 p.

4) Zhetesov S.S. Attila is our ancestor. Kazakhstan, Map named after Abylkas Saginov, 2023. – 114 p.

5) Ibatov M.K., Zhetesova G.S., Zhetesov S.S. Kazakstanyn onerkasiptik tauarlarynyn koliktik logistikas. Kazakhstan, Map named after Abylkas Saginov, 2023. – 111 p.

6) Teliman I.V. Working equipment of hydraulic excavators: methods for determining rational design and operating parameters Karaganda, Publishing House of the Map, 2023. – 110 p.

Significant publications 2020 – 2023

- Nurzhanova, O., Zharkevich, O., Bessonov, A., Naboko, Yе., Abdugaliyeva, G., Taimanova, G., Nikonova, T. Simulation of the distribution of temperature, stresses and deformations during splined shafts hardfacing //Journal of Applied Engineering Science Том 21, Выпуск 3, 2023, 837 – 845 (percentile 43, Q3)

- Zharkevich O., Nurzhanova O., Zhunuspekov, D., Mateshov, A., Bessonov A. Determination of Optimal Hardfacing Modes for Recovering Electric Motor Shafts //Tehnicki Vjesnik, 2023, 30(3), 951–957 (percentile 41, Q3)

- Gavrilin A.N., Ivanovich O.G., Grigorievich B.V., Mikhailovna Z.O., Meirbekovna, B.T. Methodology of ensuring the efficiency of mechanical processing due to the application of vibration monitoring and vibration protection means //Journal of Applied Engineering Science, 2022, 20(2), 420–431 (percentile 47, Q3)

- Zhetessova, G., Nikonova, T., Zharkevich, O., Yurchenko, V., Savelyeva, N., Berg, A., Mateshov, A. Determination of Economic Effect from the Implementation of Automated Designing Systems of Technological Processes //Tehnicki Vjesnik, 2022, 29(3), 1002–1009 (percentile 41, Q3)

- Toleuova, A.R., Dostayeva, A.M., Zharkevich, O.M., Adilkanova, M.A., Serikbayev, D. Calculating and experimental studying phase transformations in the Al-Zr-Fe-Si system alloys //Metalurgija, 2020, 59(4), 543–546 (percentile 46, Q3)

- Issagulov, A.Z., Ibatov, M.K., Dostayeva, A.M., Koshebayeva, G.K., Zharkevich, O.M. Studying the properties of refractory products manufactured by two-stage pressing under industrial conditions//Metalurgija, 2020, 59(4), 547–550 (percentile 46, Q3)

- Karsakova, N., Sherov, K., Donenbayev, B., Abulkhairov, D., Sagynganova, I., Usserbayev, M., Teliman I., Sherov, A., Tussupbekova, G. Сalculation of the boring bar design for static rigidity and strength with simultaneous boring of a stepped hole with further optimization //Journal of Applied Engineering Science, // Journal of Applied Engineering Science, 2023, Vol. 1, P.300-312. (percentile 47, Q3)

- Černašėjus, O., Škamat, J., Čepukė, Ž., Višniakov, N., Berg, A. Oscillating Laser Post-Processing of NiCrCoFeCBSi/WC Thermally Sprayed Coatings //Materials, 2022, 15(22), 8041 (percentile 70, Q2)

- Zhetessova, G., Nikonova, T., Gierz, Ł., Yurchenko, V., Zharkevich, O Preparation of the Surface of Long-Dimensional Rods of Hydro-Cylinders for Thermal Spraying Using an Abrasive Jet //Coatings, 2022, 12(10), 1514 (percentile 64, Q2)

- Nikonova, T., Zharkevich, O., Dandybaev, E., Daich, L., Sichkarenko, A., Kotov, E. Developing a measuring system for monitoring the thickness of the 6 m wide HDPE/LDPE polymer geomembrane with its continuous flow using automation equipment //Applied Sciences (Switzerland), 2021, 11(21), 10045 (percentile 73, Q2)

- Škamat, Je., Černašėjus, O., Zhetessova, G., Nikonova, T., Zharkevich, O., Višniakov, N. Effect of laser processing parameters on microstructure, hardness and tribology of NiCrCoFeCBSi/WC coatings // Materials, 2021, 14(20), 6034 (percentile 68, Q2)

- Gabdyssalyk, R, Sherov, K, Tussupova, S., Zharkevich O., Mirgorodskiy, S., Mazdubay, A., Taskarina, A., Sagitov, A. Research and quality assurance of the large valves manufacture for trunk pipelines //Journal of Applied Engineering Science, 2021, 19(1), 24–29 (percentile 52, Q2)

- Sherov, K., Mardonov, B., Zharkevich, O., Akhmedov, K., Imanbaev, Y. Studying the Process of tooling cylindrical gears //Journal of Applied Engineering Science, 2020, 18(3), 327–332 (percentile 52, Q2)

- Zhetessova, G., Zharkevich, O., Pleshakova, Y., Platonova, Y., Buzauova, T. Building mathematical model for gas-thermal process of coating evaporation //Metalurgija, 2016, 55(1), 63–66 (percentile 70, Q2)

- Nikonova, T, Gierz, Ł., Zharkevich, O., Sichkarenko, A., Kotov, E. Control of Physical Processes in an Extrusion Line Polymer Sleeves Production //Applied Sciences (Switzerland), 2022, 12(20), 10309 (percentile 75, Q1)

- K.T. Sherov, M.R. Sikhimbayev, T.G. Nasad, B.N. Absadykov, A.S. Izotova, A.E. Okimbayeva, I.S. Kuanov. The research of the steel cutting blade reliability for thermo-frictional processing // NEWS of the Academy of Sciences of the Republic of Kazakhstan (percentile 42, Q3). – Volume 1, Number 439 (2020), pp.122 – 130

- Sherov Karibek; Serova Rauza; Yessirkepova Aiym; Mussayev Medgat; Ashurova Nasiba; Mazdubai Assylkhan; Okimbayeva Asel; Smailova Baglan; Kassymbabina Dana. Laboratory tensile testing of unmeasurable parts of reinforcing bars joined by butt welding method // International Journal of GEOMATE (БД процентиль 45, Q3). – Sept. 2022, Vol.23, Issue 97, pp.196-202.

- Zhetessova, G., Nikonova, T., Gierz, Ł., Zharkevich, O, Alexey, K. A Comparative Analysis of the Dynamic Strength Properties of the Long Guides of Intelligent Machines for a New Method of the Thermal Spraying of Polymer Concrete //Applied Sciences (Switzerland), 2022, 12(20), 10376 (percentile 75, Q1)

- Imanbaev Y., Sherov, K., Mussayev, M., Ainabekova, S., Makhmudov, L. Study of Temperature Distribution in the Tool Blank Contact at Different Thermal Friction Milling Methods //International Review of Mechanical Engineering, 2022, 16(9), 483–491 (percentile 53%, Q2)

- Sherov K., Yessirkepova A., Abisheva N., Mussayev M., Zhakaba A., Ashurova N. Testing of welded reinforcing bars for elongation and process simulation //Journal of Applied Engineering Science, 2022, 20(4),–1241 (percentile 47%, Q2)

- Sherov K., Mussayev M., Usserbayev, M., Bekzhanov, Y., Myrzakhmet, B. Investigation of the method of thermal friction turn-milling of high strength materials //Journal of Applied Engineering Science, 2022, 20(1), 13–18 (percentile 47%, Q2)

- Donenbayev B., Sherov K., Mazdubay A., Mussayev M.M., Taskarina A., Tussupova S. Investigation of the method of processing holes with a rotary cup cutter with surfacing //Journal of Applied Engineering Science, 2021, 19(4), 862–867 (percentile 52%, Q2)

- Mussayev M., Sherov, K., Taskarina, A., Buzauova, T., Ainabekova, S. Chip formation during thermal friction turn miliing //Journal of Applied Engineering Science, 2021, 19(1), 142–147 (percentile 52%, Q2)

- M. Mussayev, K. Sherov, A. Buzauova T., Taskarina, A.Sherov, R. Gabdyssalik, S. Ainabekova. Chip formation during thermalfriction turn miliing // Journal of Applied Engineering Science, 2021, 1, 774, pp. 142-147 (percentile 52, Q3).

- Kunaev V., Bazarov B., Tavshanov I., Kadyrov A., Kydyrbayeva S., Абдугалиева. Evaluation of the effect of enrichment of slag aggregate for pavement subbase by grains density on its physical and mechanical characteristics //Results in Engineering, 2023, 18, P. 184-191. (percentile 74, Q2)

- Nikonova T., Gierz L., Berg A., Turla V., Warguła L, Yurchenko V., Zhunuspekov D., Wieczorek B., Robakowska M. Comparative Analysis of Strength Fatigue Properties and Abrasive Wear Resistance for a New Composition of Polymer Concrete Coated with Metal Alloy Powders // Coatings, 2023, 13, Issue 3. – P. 586. (percentile 62 %, Q2)

Scientific work with students and undergraduatesи

There are 8 student scientific circles at the department (heads: Musaev M.M., Beisembaev K.M., Nikonova T.Yu., Zharkevich O.M., Bartenev I.A., Nurzhanova O.A., Buzauova T.M., Malybaev N.S.). 10 students and 10 undergraduates participate in initiative topics of the department and state budget topics. 12 people completed term papers and theses on scientific topics. Students perform modeling of the metal cutting process in the NX program, design in the Ansys, Solidworks, Adams programs. They simulate processes in Comsol Multiphysics.

Diplomas were awarded:

– Yesyunin A. I. (magician) – Diploma of the 3rd degree (NIRS) Order No. 49 of 04/6.23;

– Smirnov A.K. – I place in the startup competition “Designing hydraulic structures” in the All-Russian Student Olympiad (NIRS) Diploma, Yekaterinburg, April 2023;

– Germasimov A.S., Romanov M.A., Smirnov A.K., Yulukov A.D. – II place in the starap competition “Designing of hydraulic structures” in the All-Russian Student Olympiad Diploma, Yekaterinburg, April 2023;

– Romanov M.A. II place in the starap competition “Designing of hydraulic structures” in the All-Russian Student Olympiad, Diploma, Yekaterinburg April 2023.

Awarded for participation in the republican student conference “Contribution of youth science to the implementation of the strategy “Kazakhstan -2050”:

– Vladislav I. Lapkin – Master’s student, gr. MSM-21-2, Karaganda Technical University named after Abylkas Saginov (scientific supervisor – Candidate of Technical Sciences, Professor Olga Mikhailovna Zharkevich);

– Vitushchenko Denis Valeryevich – student, gr. gr. MASH-21-2c, Karaganda Technical University named after Abylkas Saginov (supervisor – senior lecturer Zhukova Alla Valentinovna);

– Rubenkov Vladislav Petrovich – student, gr. MACH-20-3, Karaganda Technical University named after Abylkas Saginov (supervisor – teacher Berg Alexandra Sergeevna);

– Zhanibekov Timur Zhanibekuly – undergraduate, MSM 21-2, Karaganda Technical University named after Abylkas Saginov (scientific supervisor – Candidate of Technical Sciences, Acting Associate Professor Nikonova Tatyana Yuryevna);

– III place – Yesyunin Alan Igorevich (international research competition for students, undergraduates, young scientists in technical sciences, Gubkin, Russia, 04/6/2023)

1. Scientific activities at the Engineering faculty realized in the framework of the international, state budget, and contractual research programs and activities. international program Tempus Curricula Reform in Space Technology in Kazakhstan, Russia, Ukraine (CRIST) runs from January 15, 2009 and aims to develop educational programs, training for the aerospace industry. From the Republic of Kazakhstan in the project are: ENU. LN Gumilev and Karaganda State Technical University. Coordinates the project from the Head of KSTU, “Mechanical Engineering”, Doctor of Technical Sciences, Professor Zhetesova GS

The Working Group on KSTU training seminar (Belgium)

The result of this project was the discovery in 2010 – 2011 academic year, the department traetory new study:

– 5V071200 – “Mechanical Engineering” – Mechanical engineering, construction and production of high-tech products.

– 5V073200 – “Standardization, Metrology and Certification (by industry),” – Management of the aerospace industry.

In the framework of Erasmus Mundus Maneca assistant professor of “Mechanical Engineering” Zharkevich O. from 11.01.2011 till 01.12.2011, the training took place in Vilnius Technical University. Gedeminesa (Vilnius, Lithuania). From October 2011 on the same training program held doctoral Telenkova E. (5 months) and master’s Tattimbekova BO (5 months) (Lessius, Belgium).

Together with the Belarusian National Technical University Belarusian National Technical University within the framework of innovation and educational center in the field of engineering is carried out jointly research project on “Creating Multifunctional nanostructured coatings obtained by electrophysical methods with the aim of strengthening parts of mining equipment.”

10.08.2011, the Head. Chair, “Manufacturing Engineering” Prof. GS Zhetesova participated in the meeting of working committee for the coordination of scientific educational consortium between universities and research institutes of the RK and Belarus. 11/15/2011 in Minsk Ph.D., assistant professor of TM tumens TN participated in the forum “Belarus Innovation Week.”

The total volume of executed state budget, scientific and contractual work is 102.312 million tenge.

scientific activities of state budget programs of research carried out on the following topics:

– “Development of technology for the application of nano metals and alloys by surface modification of materials with various reagents to the regulation of the emerging nanostructures for use in pumps, homogenizers oil and gas industry of Kazakhstan», № 173 of 01.03.2011, the, MES, 2.5 million tenge (Department of TM).

– “Development of technology for production of nanostructured materials with desired mechanical properties», № 172 of 01.03.2011, p CN MON -2.25 million tenge (Department MMiN).

Principle raboty planetarnoy melnitsy

– “Development of technology for the production of nanostructured metal by combining the processes of casting and punching in the equal-channel step-matrices (Komsomol)», № 5 dated 10.12.2010 with JSC “Fund of Science” – 20 million tenge (Department MMiN).

A sample consisting of colored particles in the original provisions in the inclined section of the channel matrix

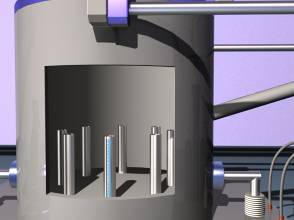

Smelting of aluminum samples in the RPC-120-3

– “Increasing the corrosion resistance of metals by using galluazitovyh nanotubes”, JSC National Innovation Fund, 19 million 681 thousand tenge (Department MMiN).

– “Obesfosforirovanie Lisakovsk iron ores by chemical methods”, JSC National Innovation Fund, 19 million 681 thousand tenge (Department MMiN).

– “Design – technological and instrumental quality assurance parts of mining equipment, mining and processing equipment to enhance its operational stability», № 371 of RK-30 million tenge. (Dept. of TM).

MODEL project

The application of carbon-nitrogen coatings

the inner surface of the cylinder,

hydraulic rack

scientific activity on the orders of enterprises is carried out on the following topics:

– “Development of technology of repair and restoration of the guide parts of machine tools and manufacturing equipment,” economic contracts subject to the LP “Karaganda Engineering Consortium” at $ 1.7 million tenge. (Dept. of TM).

– “Technological support surface quality rods, hydraulic cylinders with a diameter exceeding 150 mm surface plastic deformation of the rollers’ economic contracts subject to the LP” Karaganda Engineering Consortium, “$ 2.5 million tenge (Department TM).

– «Development of the technology and equipment of cutting slyabingovogo rolled in continuous casting of steel” economic contracts with the theme “VTORPROM” $ 4 million tenge (Department SiLP).

Thermal cutting of slab continuous casting of steel mill

01/12/2011 Zhetesova GS, Yurchenko VV participated in the 1st forum of scientists in Kazakhstan, the 20th anniversary of Independence of the Republic of Kazakhstan which presented the layout on « Design – Quality Assurance process parts of mining mining equipment to enhance operational stability. ”

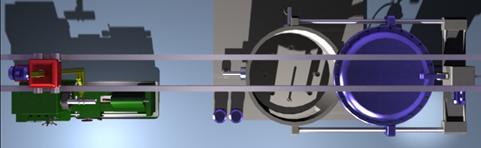

Project layout (front view, top view)

To implement the project MI was created in the design office with the participation of doctoral students, graduate students and faculty.

In November 2009, Associate Professor of TM Zharkevich O. won the scholarship of Japanese firms’ Tokyo Boeki CIS »for success in learning and research activities.

In 2010 Senior lecturer Department of Nikonov TM TY received a grant from “Fund of First President” on the passage of scientific training in the Technical University of Berlin, Berlin (Germany).

In October 2010 the head. Department MMiN Kulikov VY and assistant professor of TM Zharkevich O. Scholarships have been awarded research for talented young scientists.

In August 2011 received a confirmation of the degree of Doctor of Technical Sciences Professor MMiN Tursunbaeva AK

Professor of MMiN Turdukozhaeva AM 16.09.2011g. elected as a member of the International Academy of Informatization.

In 2011, USX vice-rector for Yee, Professor, Department MMiN Isagulov AZ won the award “Zamandas” in the “Pride of science.”

At the end of the republican contest “The best teacher of high school-2011” state grant holders are Professor TM Sherov KT and Professor of Yixing MMiN DC

The basic research results for 2011 published in the journals of rating of Kazakhstan and abroad:

Department MMiN 23 articles

Chair TM 15 articles

Department of SLIP 1 article

Department of Linguistics 12 articles

During the period of 2011 Scholars received six applications for innovation patents and received two innovation patents RK.

MMiN Department received four applications, received a patent

TM Department filed two requests, received a patent:

In 2011, Associate Professor, Department Buzauova TM TM received approval of a scientific degree of candidate of technical sciences in specialty 05.05.06 – Mining Machines (05/05/2011 city).

In December of 2011 were protected by two doctoral dissertations (PhD) Director of IM Sharoi O. and senior lecturer at the Department of TM V. Yurchenko

in 2011 were protected by 16 master’s work in the field of “Metal”, “Materials Science”, “Engineering”, “Standardization, Metrology and Certification.” Academic master’s degree was awarded: Abiltusupovoy D. Kadenovu R. Makaeu S., Tian, E., A. Sadvokasovu, Nurmagambetova D. Korotlevoy A. Duysenbekovoy L. Baydauletovoy I., A. Antipova, Iskakov B Senina E., E. Pleshakova, Biyzhanovu C Karsakovoy H Gerasimchuk A., V. Tymoshenko

The scientific adviser Prof. GS Zhetesova and graduate chair TM

(Karsakova N. Senin, E., Gurasimchuk A., E. Pleshakova)

In January of 2012. were protected by 11 master’s work in the field of “Metal”, “Materials Science and Technology of New Materials”, “Engineering”, “Standardization, Metrology and Certification.” Academic master’s degree was awarded: Sisekeshevu KM, Kultanovoy MT, Muhangalievu EK, Aydarbekovu N., Belousova VS Dostaevu AM, Sultanbekova EB, Old H . S. Leshchenko MS, Zhunuspekovu DS, AN Tkachev, Moldagali BJ

In July 2011 the winners and prize holders (200,000 tenge) branch at the National Competition of Kazakhstan “Golden Hephaestus” in the “Best Student Thesis” included: student chair MMiN Abaeva Milan Musaevna and Baydurina Gulnara Kusainovna.